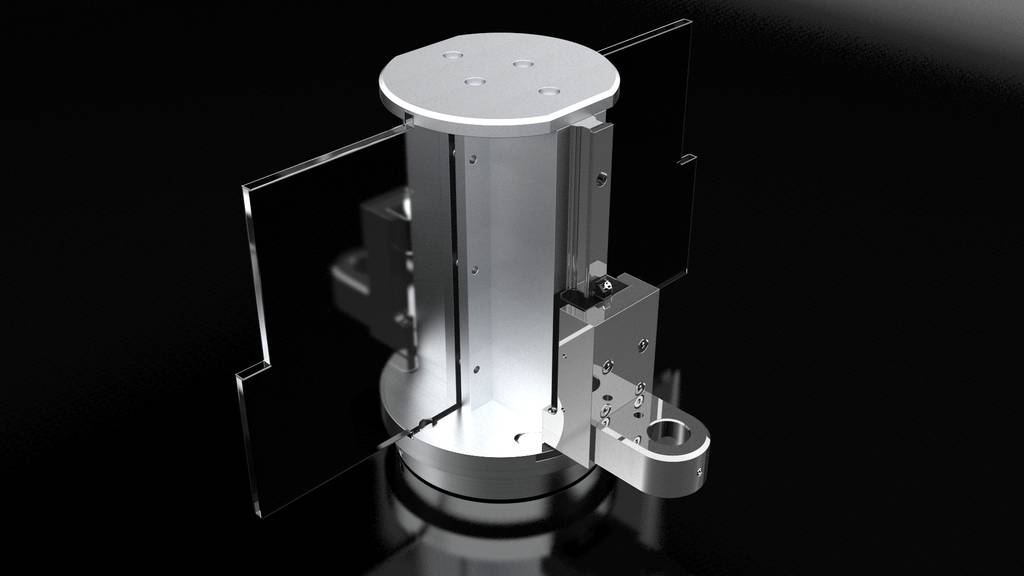

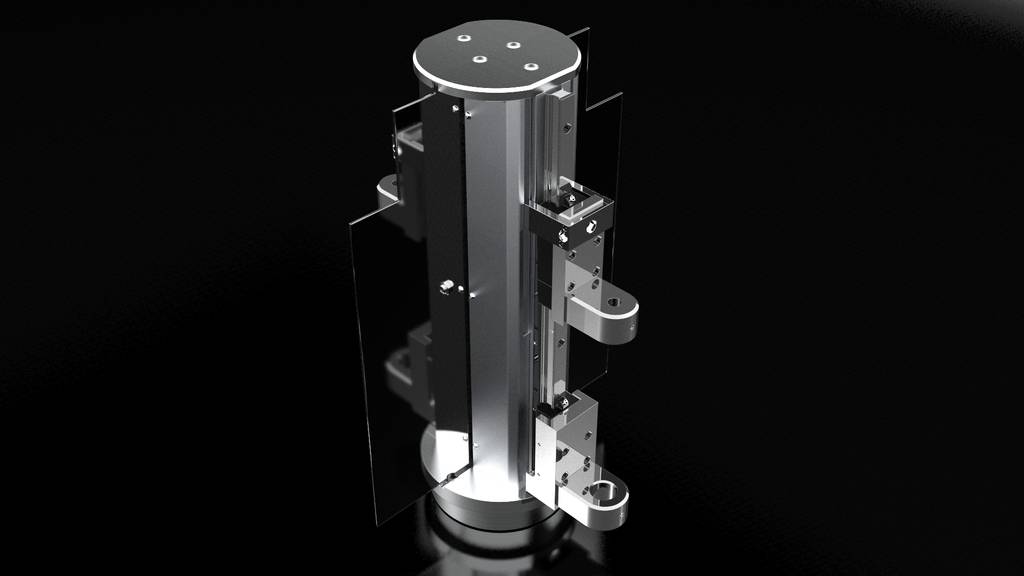

- Force range: up to 3 kN

- Stroke: 75 mm

- Workspace: 180 mm

- Outreach: 45 mm

- Operating speed: 150 mm / s

- Ideas are our core competence

- +49 7723/925-0

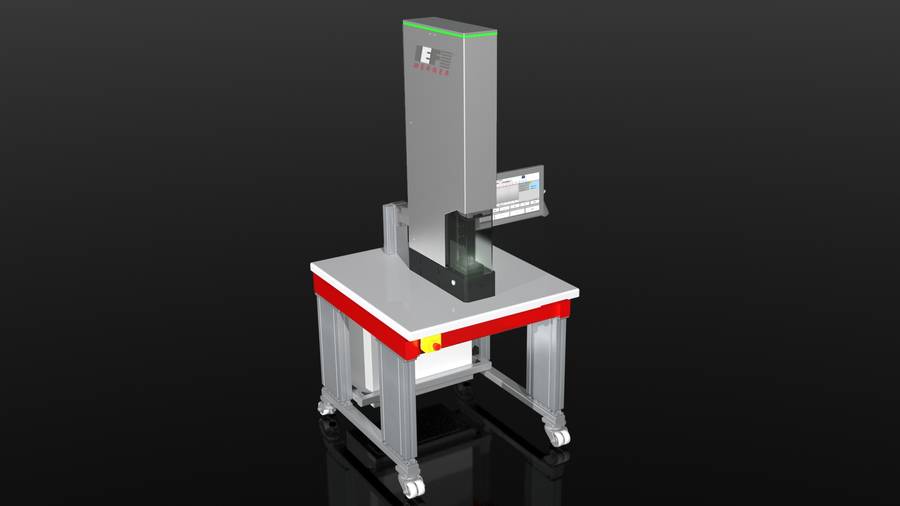

Servo presses

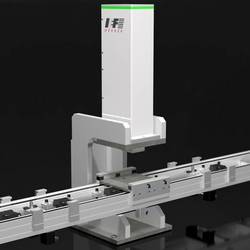

aiPRESS servo presses for high-precision joining connections

![[Translate to Englisch:] aiPRESS 360 | IEF-Werner](/fileadmin/_processed_/4/2/csm_aiPRESS_360_slow_9dd3d1f56b.gif)

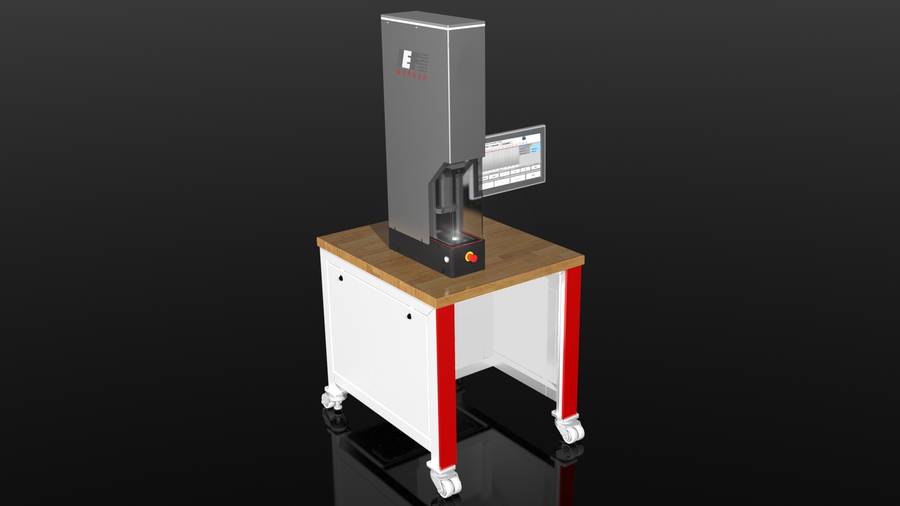

aiPRESS servo presses are used to produce safe and reproduceable joinings. They offer optimal possibilities in customising the joining process to your needs. Process factors such as feed force, running speed, positioning time and accuracy can be adapted precisely by using a large number of optional components.

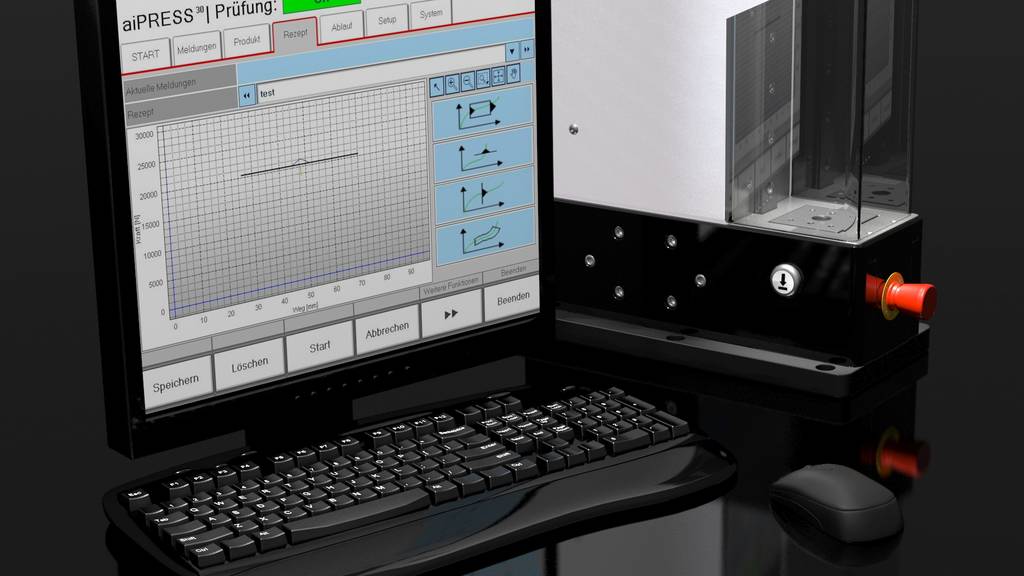

aiPRESS servo presses are serially equipped with monitor, keyboard with mouse as well as compact control cabinet with pluggable cable set. Optionally, the system can be amended with a high-quality multitouch user panel inclusive holder.

A concept that has been well proven: More than 800 IEF servo presses work reliably around the world - in rough industrial environments.

aiPRESS | automatic intelligent pressing

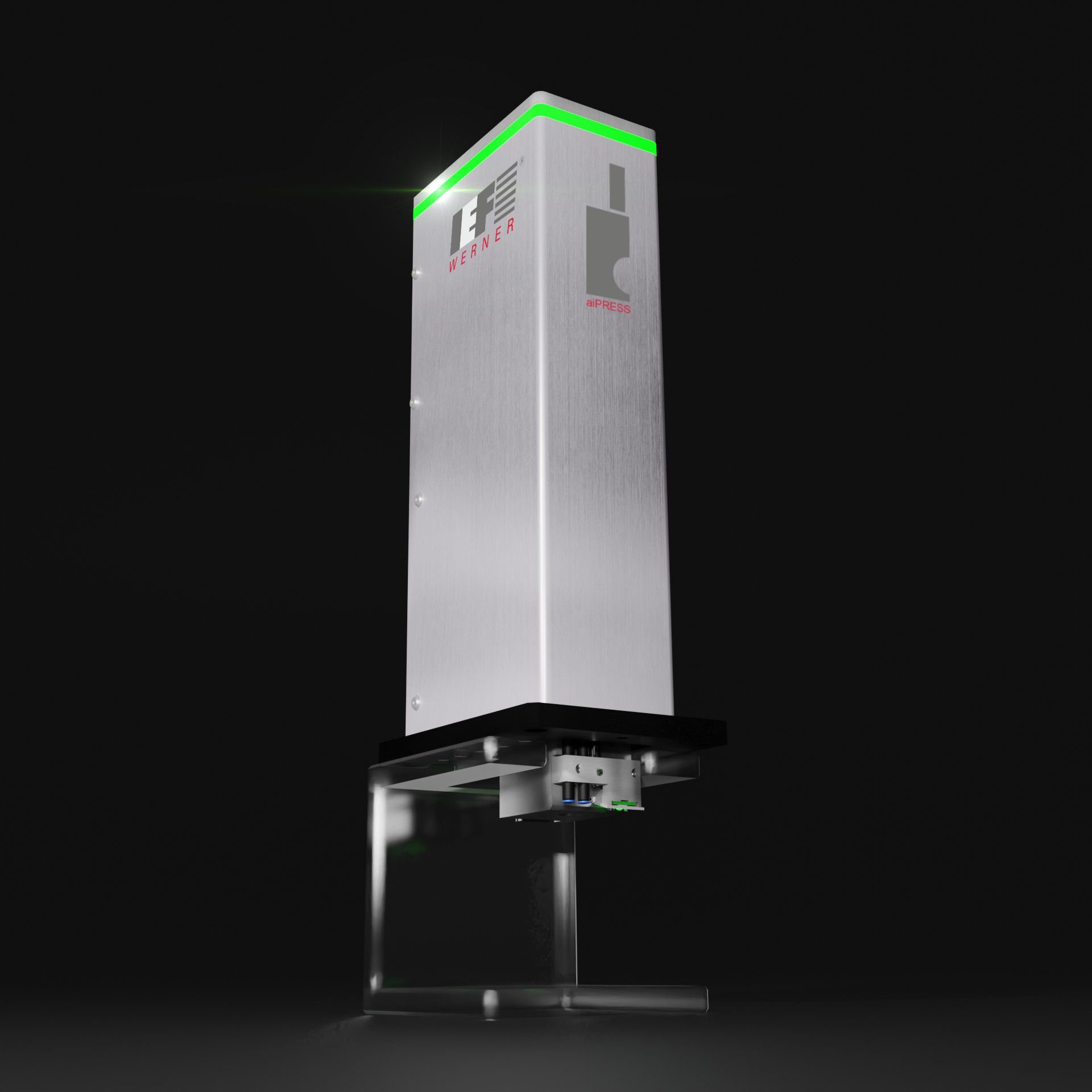

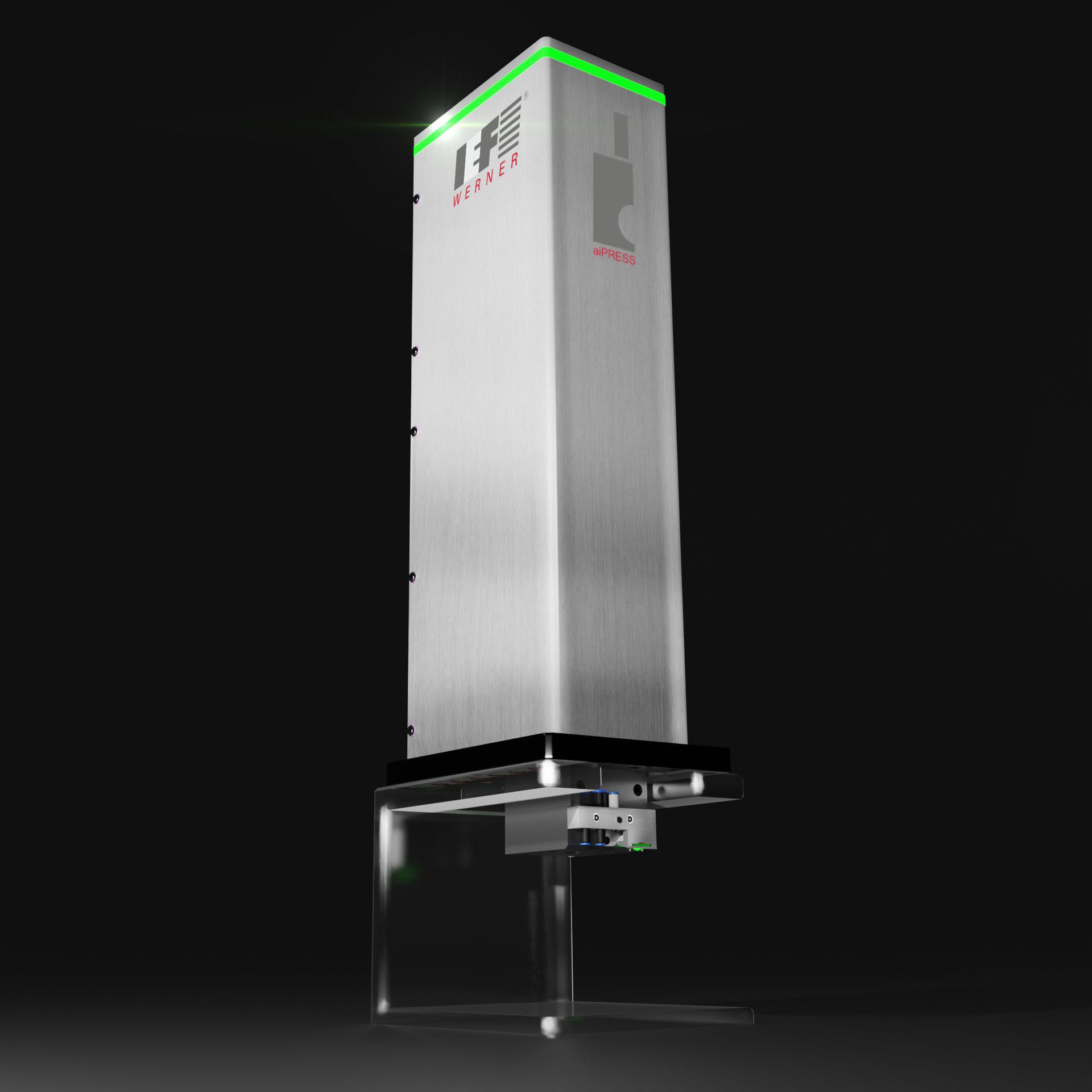

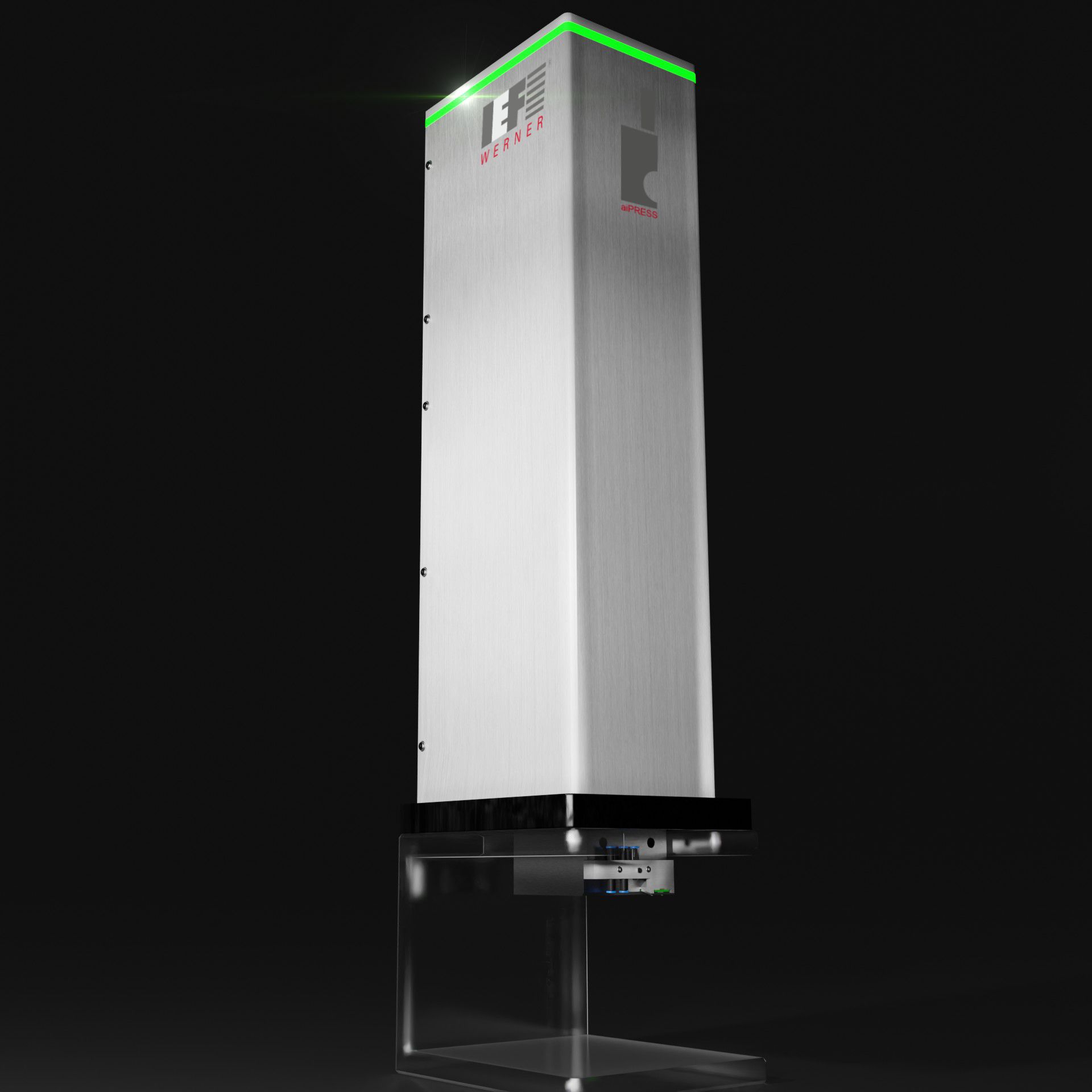

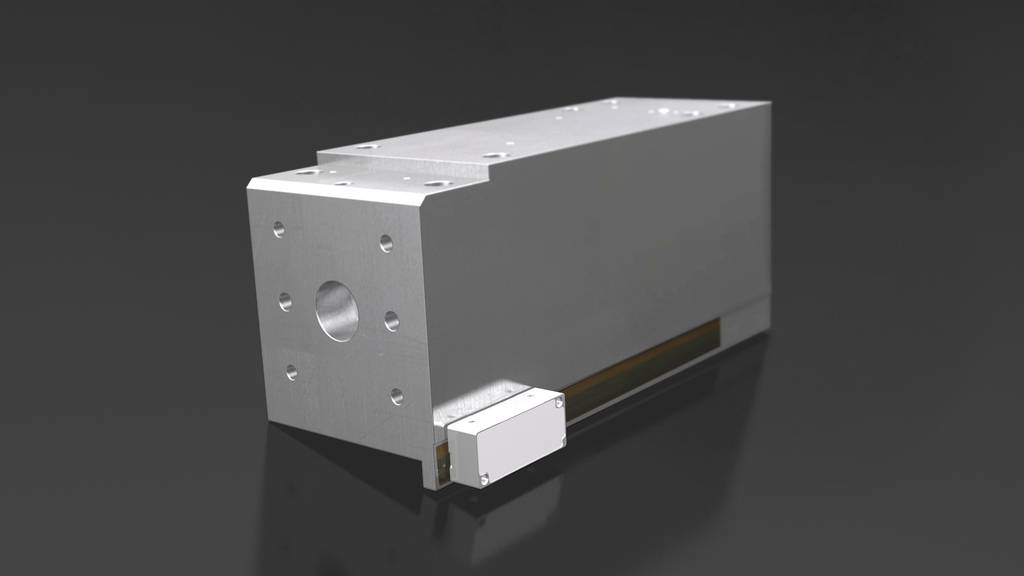

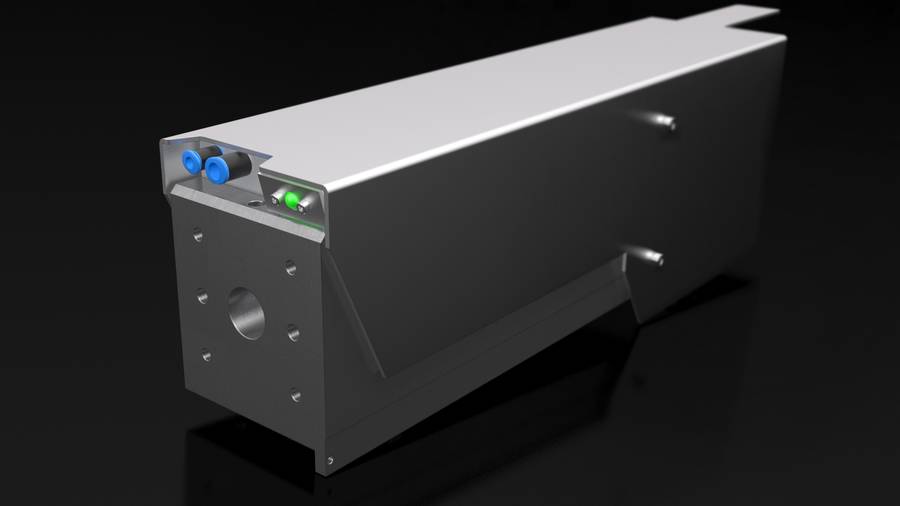

aiPRESS JM-Joining Modules to be Integrated into Your Special Machine

The servo motor joining modules aiPRESS JM can be installed in any orientation (e.g., upside down). The integration into your machine control system takes place simply via the proven press control aiQ-CONTROL.

aiQ-CONTROL enabled complete monitoring and control of press-fit or joining processes. All systems and accessory components of the aiPRESS family are extremely user-friendly and offer a high degree of flexibility for simple to highly complex joining processes. IEF-Werner joining modules are typically used in fully automated handling and assembly lines, e.g. as a joining station within a posyART transport system.

The joining modules are produced from our standard components, which are in stock and therefore we guarantee a fast delivery.

- Control system with graphical user interface (curves, windows and force-distance barriers)

- Position measuring system with repeat accuracy < 0.002 mm

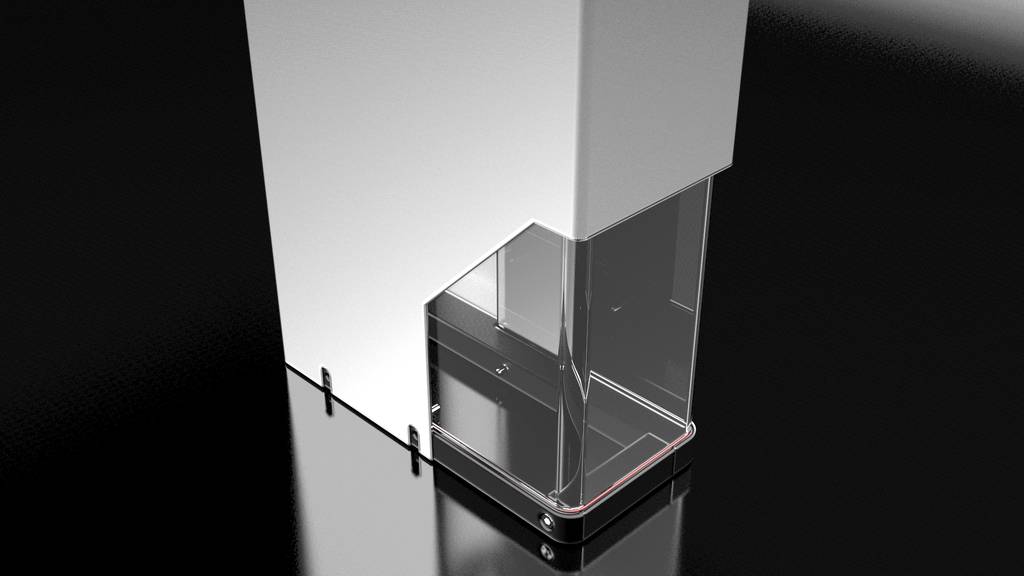

- Compressed air / vacuum supply directly to the press quill

- Small size

- High travel speed up to 150 mm / s

- Force ranges up to 36 kN

Application examples

-

Servo press aiPRESS

-

How to: Setting up an aiPRESS

-

Application example: Imprinting

In this application the servo press aiPRESS 36 is used for reliable and reproducible stamping. The force range of the press reaches up to 36 kN. The process visualisation aiLIGHT with energy-efficient, glare-free four-colour LED technology signals the quality of each press result. The operator is thus immediately provided with all information necessary for operating the machine. For a more detailed view of the pressing result, a view of the control console is of course necessary despite the aiLIGHT. The force-displacement monitor with the ergonomic and user-friendly software aiQ-CONTROL displays the pressing processes graphically in real time and monitors the progress.

-

Application example: Testing springs

The demo application to test springs consists of a combination of different IEF-Werner standard components. A 3-axes handling is installed in the application. This handling system with gripper picks up the springs, which are to be tested, from a nc-turning table DT 80/100, which is used as material buffer. The springs are inspectet of a camera. A combination of the manual adjusters domiLINE is doing the fine-tuning of the camera. The handling places the spring in the servo press aiPRESS, which carries out the testing and transmits the results to control.