- Ideas are our core competence

- +49 7723/925-0

Turntable

Turntable for changing loads

Turntables are needed for efficient processes and high cycle times. Equipment and pressing or joining can be performed simultaneously. Turntables are produced according to customer specifications only.

Hereby you benefit from our engineers' long-term experience. Important keywords are:

- work safety

- weight decoupling of the tool holders

- opening and closing of the tool devices

- NC-rotary drives or cycle machines

- tool change systems

- integration in production lines and automation

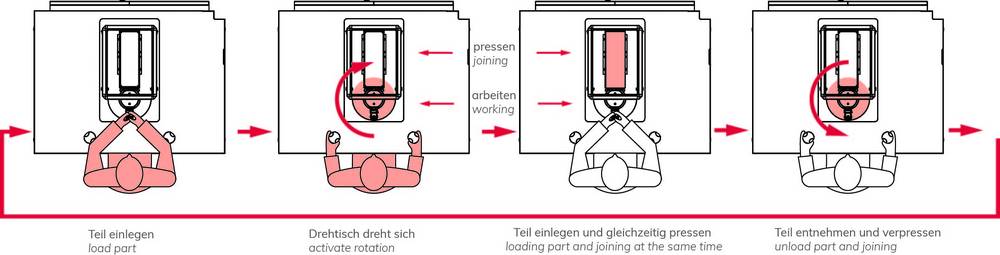

Working method

- The operator places components into the lower and upper stamp.

- The operator triggers the joining process by activating the two-hand control. The rotating unit turns by 180° towards the pressing unit.

- The press quill moves down and joins the components to one finished part. While the pressing unit joins the components, the tool can be equipped again.

- The operator triggers the joining process by activating the two-hand control. The rotating unit turns back in the opposite direction. Finished parts can be removed and components can be inserted.