| stroke (stroke increments 30 mm) | 60 - 1440 mm |

| temperature range | 0 - 60 °C |

| weight basic slide unit (60 mm stroke) | 7.1 kg |

| weight increase (per 60 mm stroke) | 0.76 kg |

| weight carriage (185 mm long) | 2.4 kg |

| possible spindle pitch | 5/10/20 mm |

| repeat accuracy | +/- 0.02 mm |

| process accuracy (at 500 mm stroke) | <= 0.04 mm |

| spindle pitch error (at 300 mm stroke) | <= 0.05 mm |

| load rating linear guide system dyn./stat. | 29/48 kN |

| geometrical moment of inertia of the basic body | Ix 556.861 mm4 / Ix 5.990.836 mm4 |

| basic friction torque | 0.3 Nm |

- Ideas are our core competence

- +49 7723/925-0

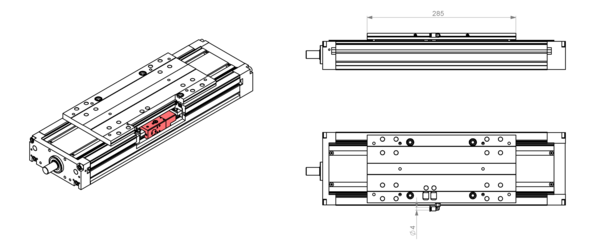

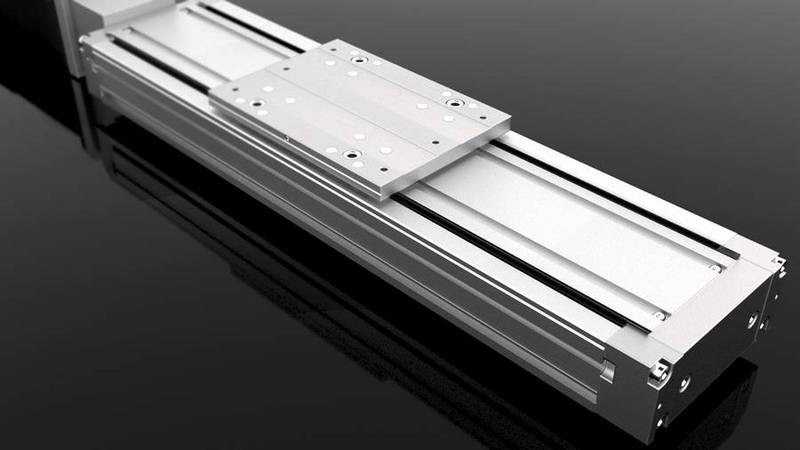

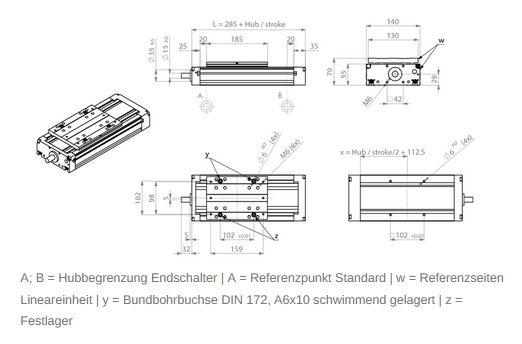

profiLINE 140

- Product type: Linear drives

- Download

- CAD data: profiLINE 140

- CAD data: Levelling elements

- Operating instructions

-

Technical details

-

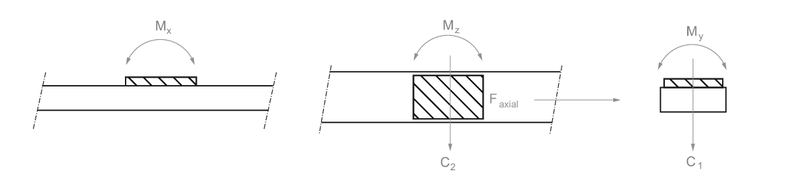

Loading details

-

Motor assembley variants

Motor assembly variants

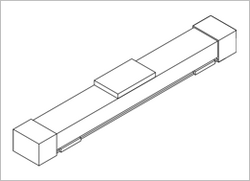

Variant 0

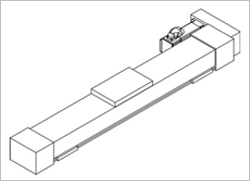

Variant 1

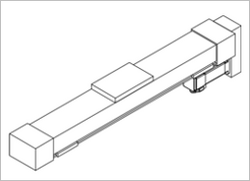

Variant 2

Variant 3

Variant 4

Variant 5 The motors are attached either directly via flange and coupling or via almost backlash-free belt gear. Different attachment versions and gear ratios are available. Attachment type and gear ratio can be changed easily even subsequently.

-

Pneumatic locking brake

Features

Note: The locking brake serves as a redundant brake and may only be used in addition to a motor brake or other primary brake.

- holding force of 400 N

- closed without energy

- pneumatic opening

- up to 5 million static clamping cycles

- up to 500 dynamic braking cycles

The linear unit with braking element LBPS is designed exclusively for operation with compressed air. It is not suitable for operation with other media. According to EN ISO 13849-1, the integrated braking element is a proven component of control systems. The element can be used in category B or 1 control systems without any further control measures; a test channel must be provided for category 2 control systems. For use in higher control categories, the control must be multi-channel, whereby each channel must implement the safety function on its own.

-

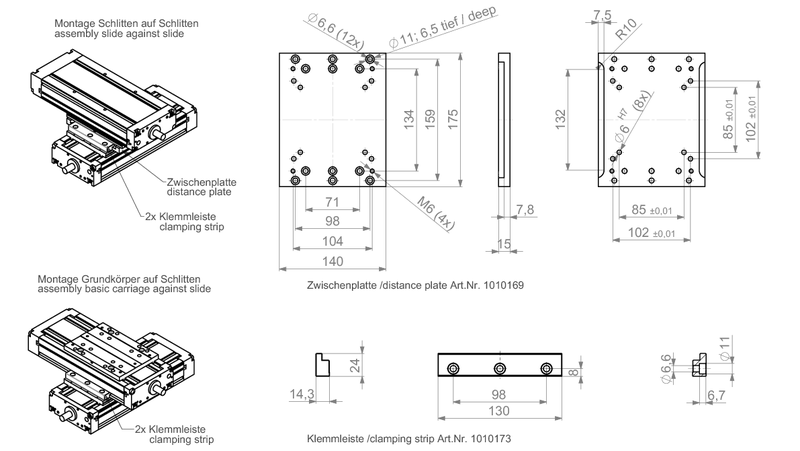

Accessories: XY-Assembly

-

Accessories: Cross mounting

-

Accessories: Clamping strips

-

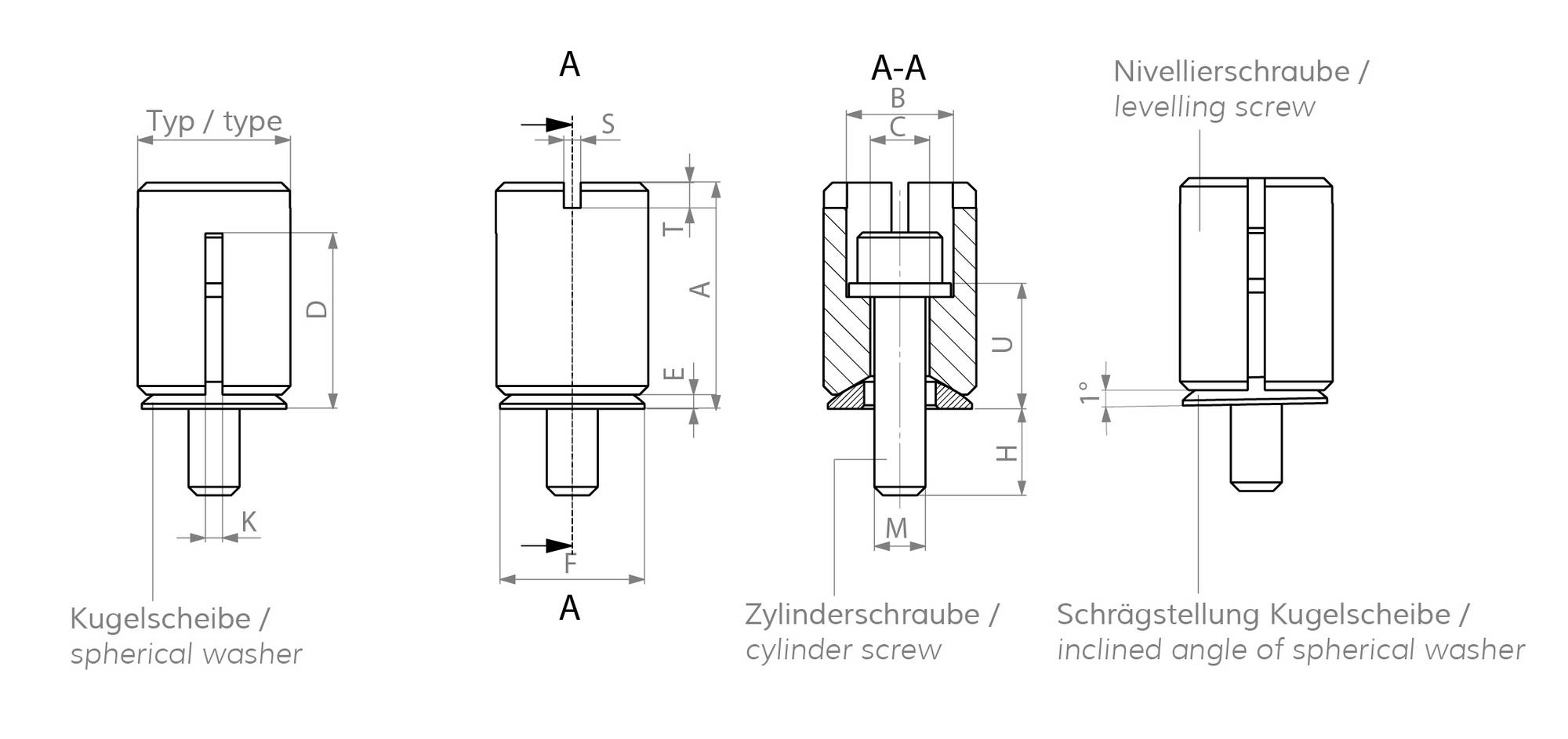

Accessories: Levelling elements

These elements are ideal for the levelling of assembly surfaces which cannot be mechanically processed or only with great effort,. You can find more information and helpful tutorials here.