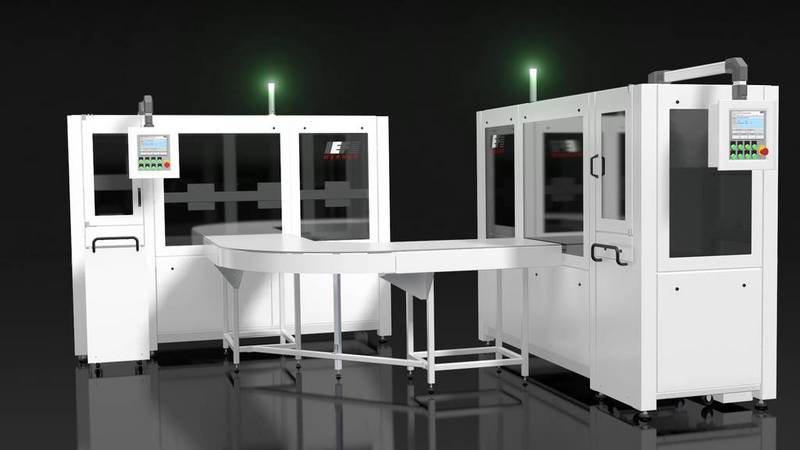

In the first step the pallets from the loading system are checked. To ensure that the right products are fed to the production line, each pallet is provided with an RFID tag. With its adapted pallet gripper, the lifting axis takes the top pallet out of the trolley and moves it to a transponder that reads the RFID tag. If the data is correct, the handling unit removes the topmost product from the pallet. A scanner reads the barcode, sensors also measure the thickness. The system compares the data with the order in the operator's MES. The handling unit then places the plate on the conveyor belt for further processing by the customer. To ensure that the intermediate layers do not stick to the product, an air pulse is emitted from a blow-off pipe in parallel during removal from the pallet. The gripper then transports these intermediate layers into the storage provided for them, the empty pallets into its buffer storage. The unloading system carries out the same steps in reverse order. This means that the finished products, which return from the customer's processing stations with the conveyor belt, are reloaded into the empty pallets after the MES check.