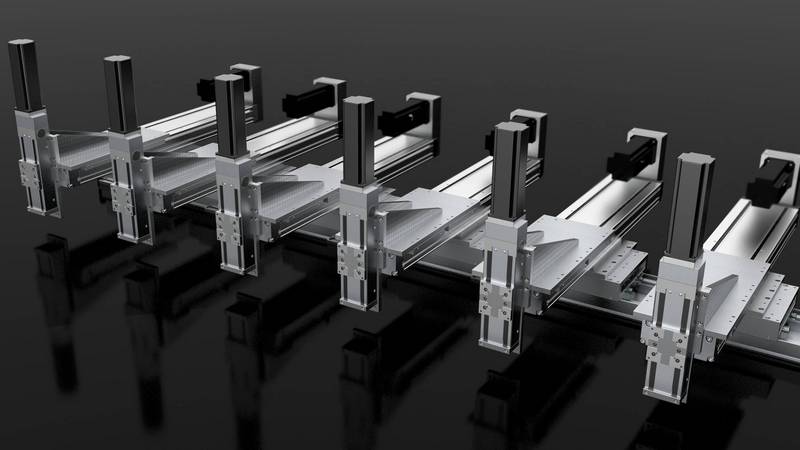

The 18-axis positioning system is used for mounting sensors. The various components of the sensors are fed individually depending on the processing step and precisely assembled in six processing steps such as pressing, screwing or gluing to form finished assemblies.

The traversing range per station is 150 x 510 x 80 millimetres, the processing time for the various machining steps is between four and eight seconds, depending on the task. The quality of the individual steps is checked by a customer-side camera system. Thanks to the 18-axis positioning system, these six handling processes could be implemented in a very small installation space.

A linear unit from the euroLINE series is used as the X-axis. The required six slides of the processing stations are accommodated on the individual axis basic body. In order to achieve the safety level required by the customer, the linear motor was also equipped with a special absolute encoder, which allows operation at a safely limited speed.

Spindle axes of the profiLINE series were used for the Y and Z axes. The spindle-driven linear rails with recirculating ball bearing and guideway assemblies are ideally suited to handle small parts precisely.