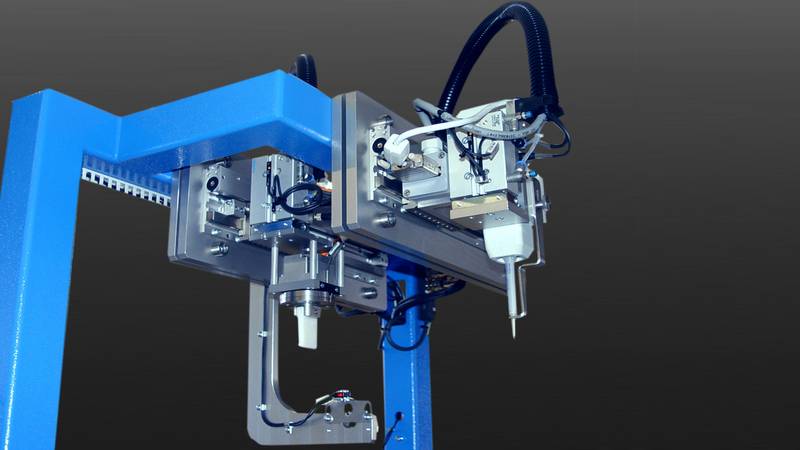

For assembly of turning fork sensors, a dosage & turn-in station was developed that bonds and joins its main assemblies. In the first assembly step, Piezo drives are put onto workpiece carriers and pushed into drawers. There, they are lifted up and relocated onto the linear units' tappers. The next step comprises of application of glue and putting on tuning forks. Then the tuning forks are turned in to spread the glue. At the end of the assembly process, finished parts are supplied to a second drawer and manually removed.

- Ideas are our core competence

- +49 7723/925-0

Dosage & turn-in station

- Product type: Customer applications

Dosage & turn-in station

-

Application

-

Features

- Insert station with drawers for supply or removal of components

- Heavy load table with height adjustment permits ergonomic work

- Linear units of type Module 80/15 for movement of workpiece carriers

- Reading heads for recognition of workpiece carrier's types

- Integrated control cabinet

- Protective housing

-

Technical details