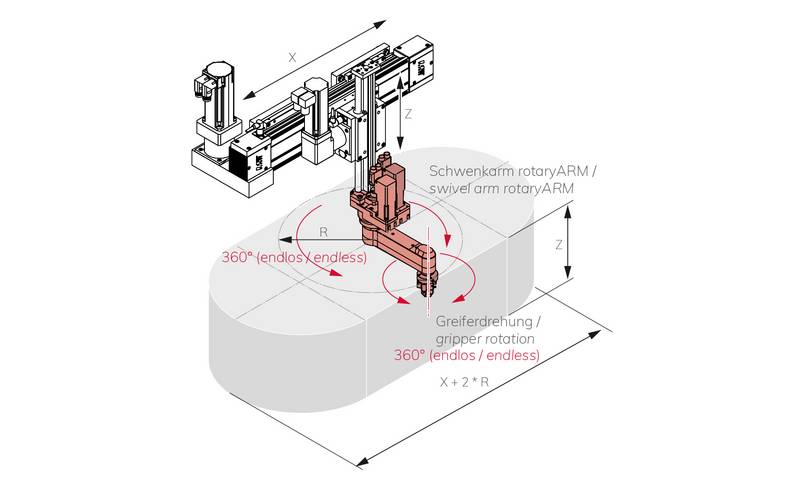

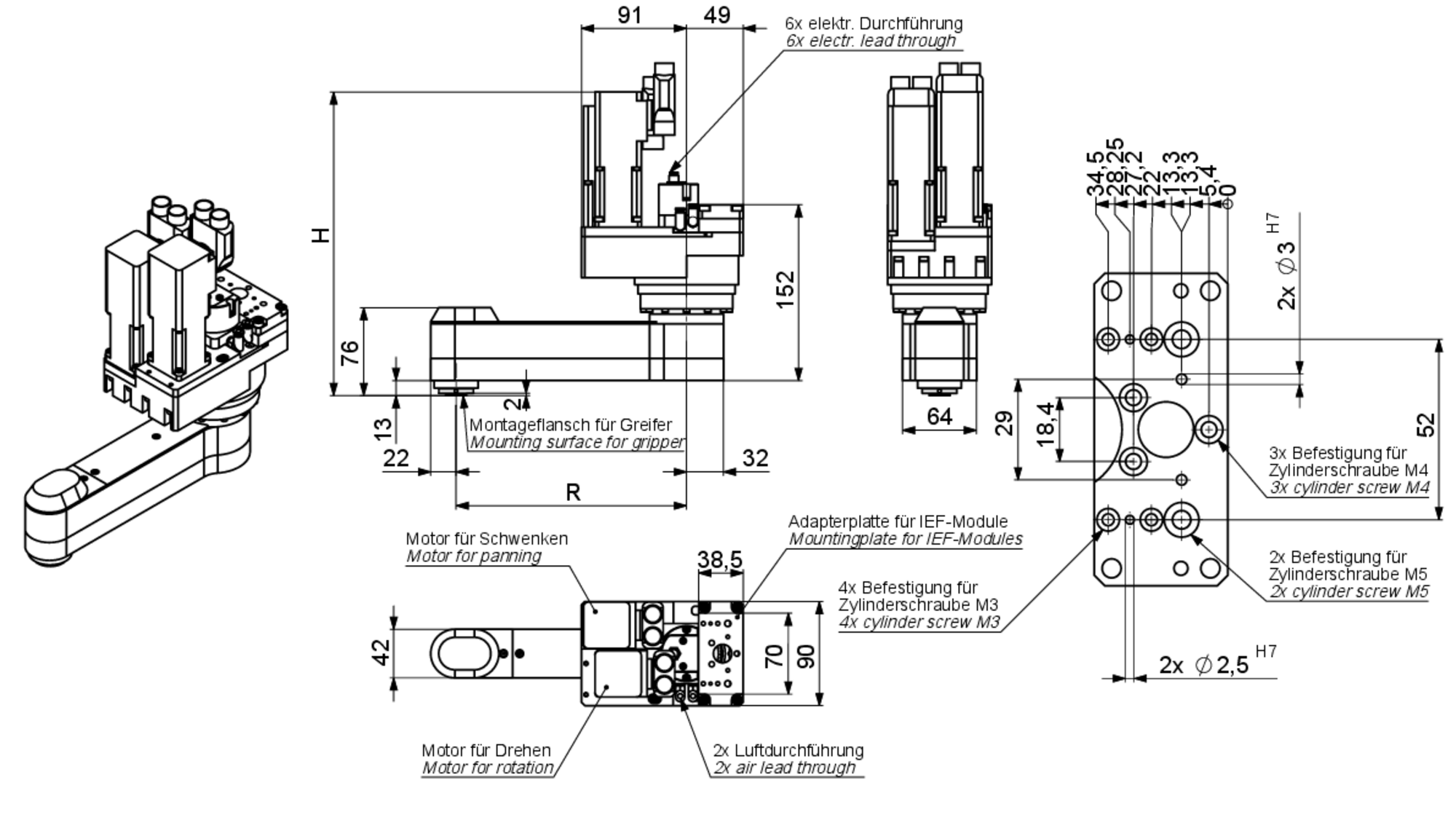

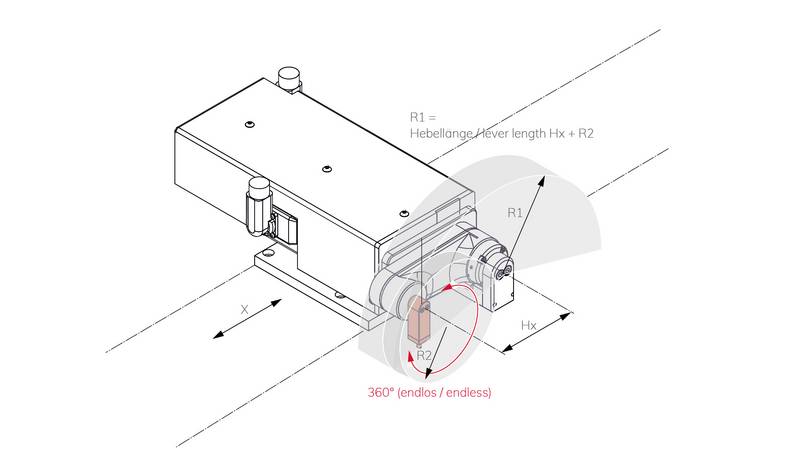

The rotaryARM swivel arm module in combination with linear units is a very fast pick & place system for all tasks that require a fast and precise automation solution. The radius range of the working area is 148, 199 or 268 mm.

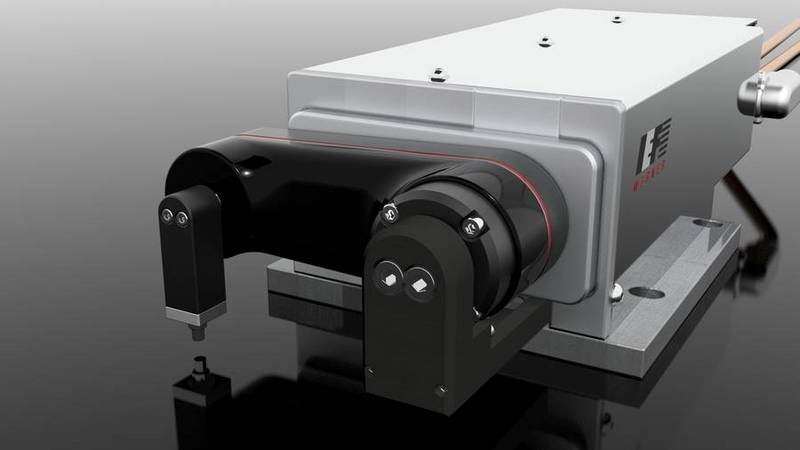

The module can be used for all assembly, handling, packaging, palletising and other applications that require a fast and precise automation solution. It is optionally available with an additional NC rotary axis for the gripper. In the new generation, the rotaryARM's swivel and rotary axes can be rotated endlessly. This is made possible by a rotary feed-through for electrics and pneumatics integrated in the swivel arm. This also eliminates the need for an additional cable carrier. Other features include high rigidity, low dead weight and motors with absolute encoders.

Features

- NC-swivel arm module with optional turning axis

- Endless rotation with swivel and turning axis

- Large working area with compact dimensions

- Short cycle time by overlaying speed of swivel arm and linear axis

- Rotary feedthrough for pneumatics and electrics integrated in the swivel arm, thus no additional energy chain necessary

- Servo motors with absolute encoder

- High resolution in swivel and turning axis

- High stiffness

- Low net weight