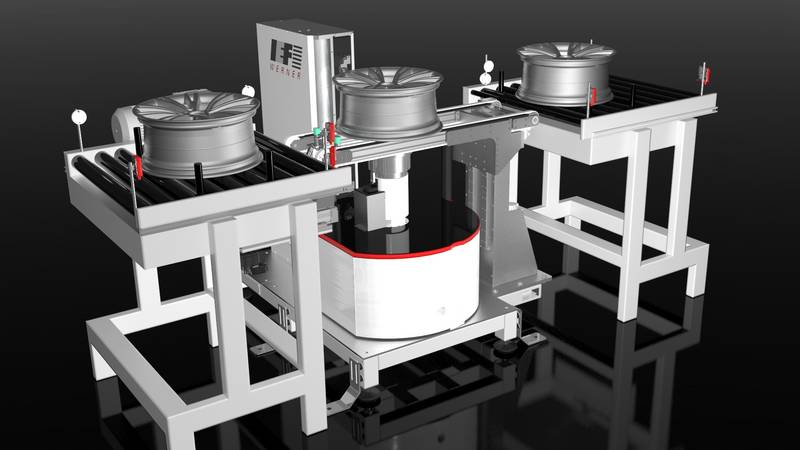

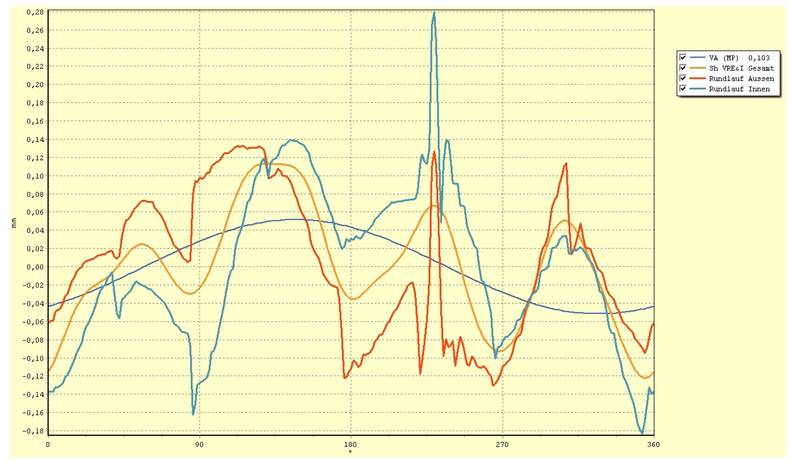

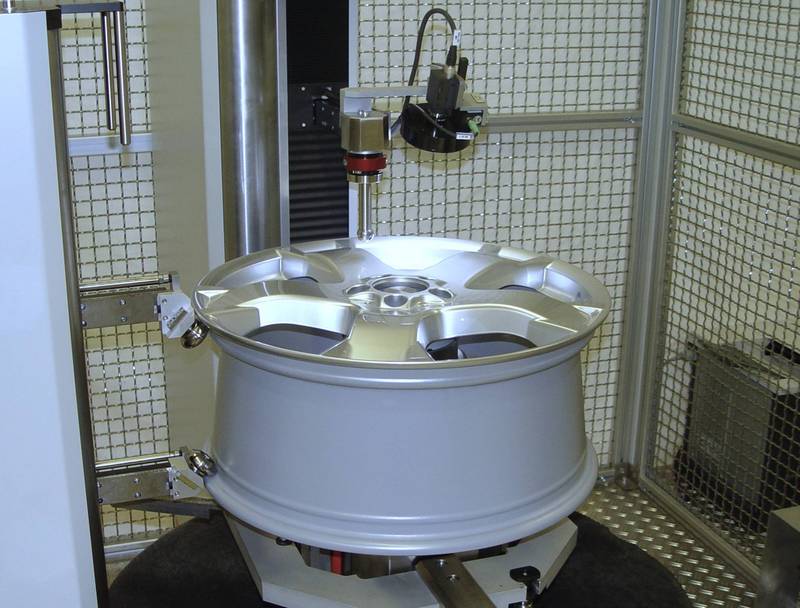

The patented R2010 wheel measuring machine was developed to measure geometric features at car wheels. It combines the function of measuring value recording, measuring process, calculation and illustration of the measured features in a single device. The wheel measuring machine R2010 for 100% inspection is a fully automatic system to be integrated into production lines. Mechanics, electronics and software are built in modules and configured individually according to customer's specification. The individual components are set perfectly for each customer by integration of state-of-the-art technical developments from the areas of information technology, optics, laser and drive technology. The shortest measuring times at the highest precision and repeat accuracy will be achieved by using IEF linear modules with innovative drive technology. Calibration of the wheel measuring machine takes place by setting master.