smartly moved!

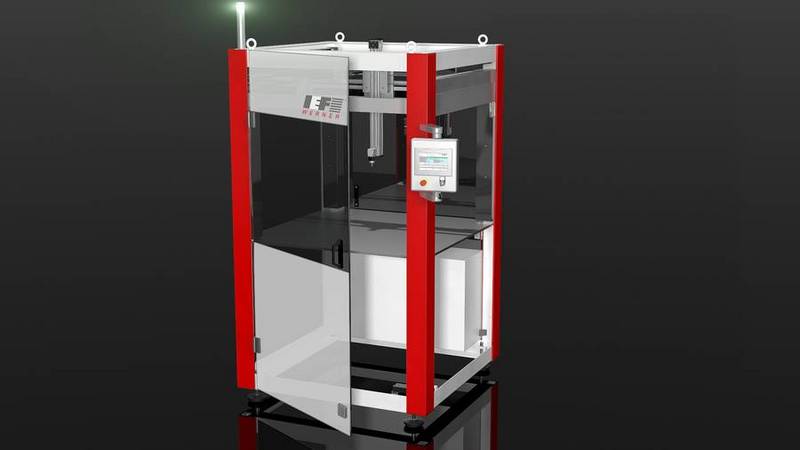

The standard cell roboCELL is the starting point for automated production processes. The modular concept allows the adaption to your individual applications.

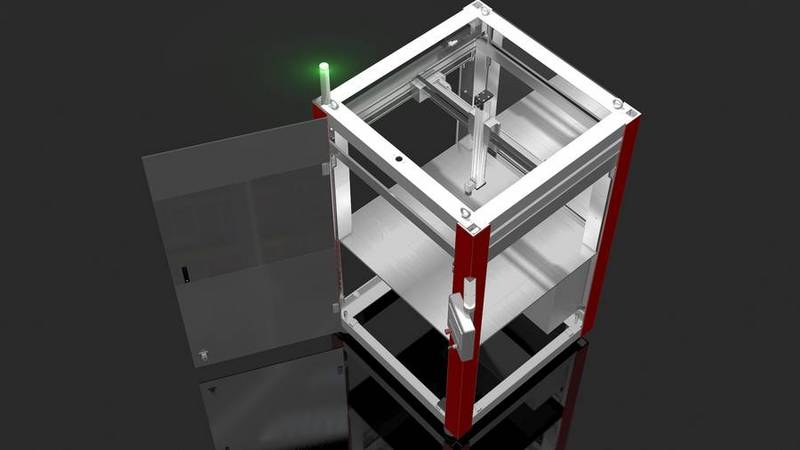

The system is built on a self-supporting steel frame and forms a forklift- and crane-accessable unit. The required space is only 1.4 m2 (1310 x 1310 mm). The base frame includes a Cartesian arranged XYZ-positioning system, a control cabinet as well as a base plate. This plate is installable in various heights and forms the basis for your individual machining, conveying, joining or assembly applications. All drive motors of the XYZ-positioning system are stationary attached, i.e. no motors, gearboxes or cables are moved along. This reduces the cycle time and increases the payload of the handling.

By the use of standardised modules the costs are clearly calculable at any time. A variety of optional components completes roboCELL according to your conceptions. For the flexible and reliable implementation of your automation process for example the transport system posyART or the palletising system smallSTACK are available for integration.

The roboCELL is equipped by default with the control unit Beckhoff 7" Panel-PC CP67xx. With the basic software WINPAC - in addition to numerous I/O modules - up to 13 motors can be driven.