space-saving and universally applicable

- Ideas are our core competence

- +49 7723/925-0

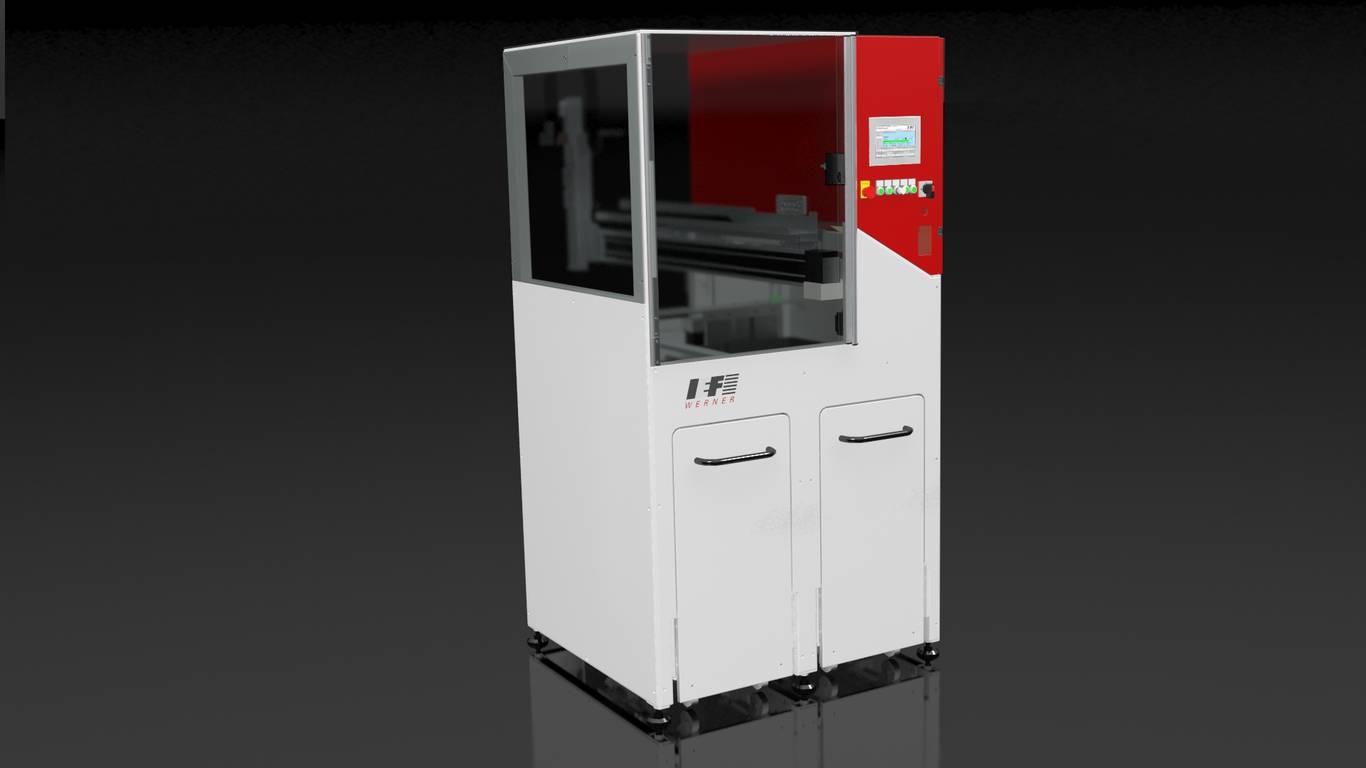

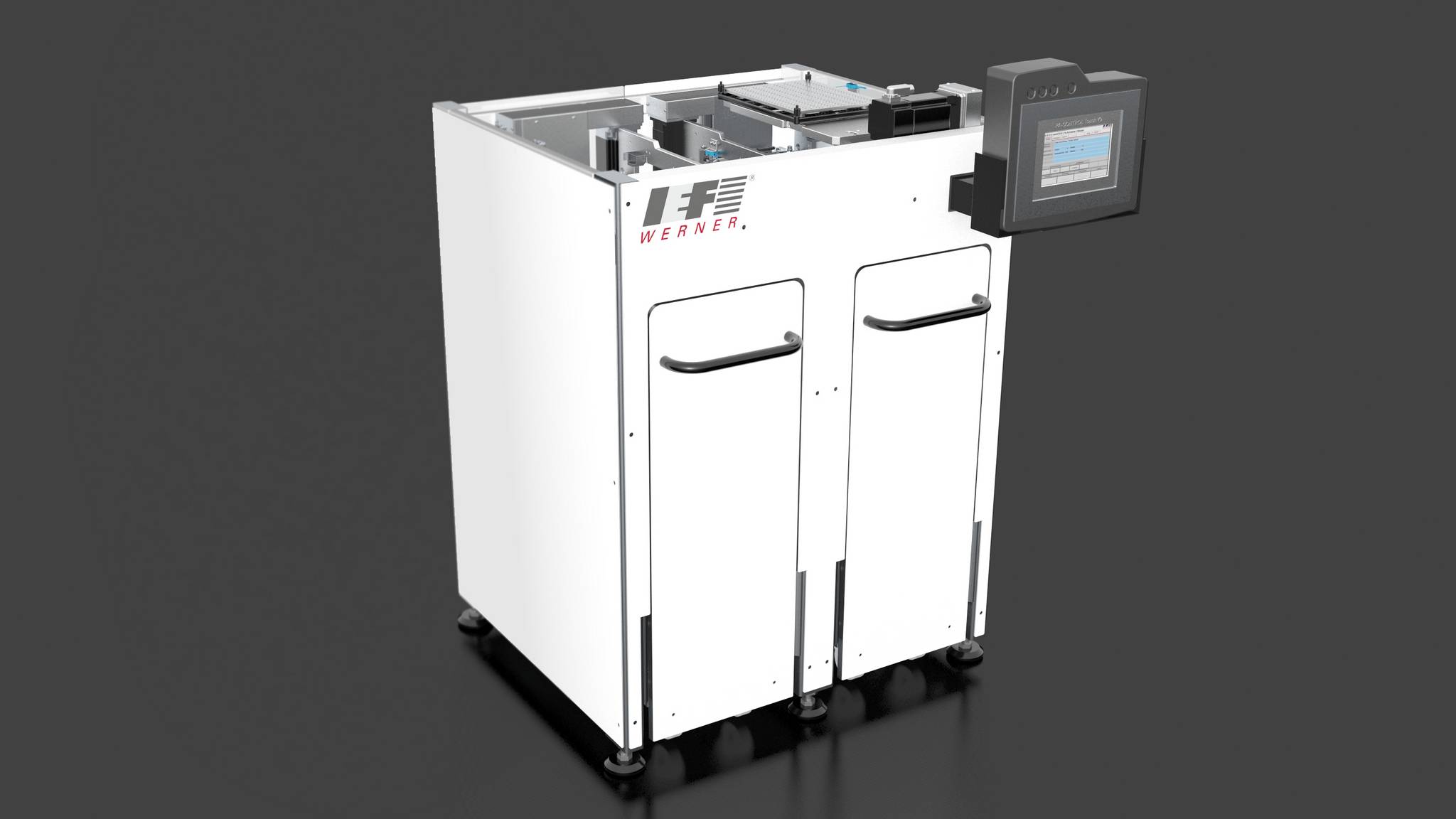

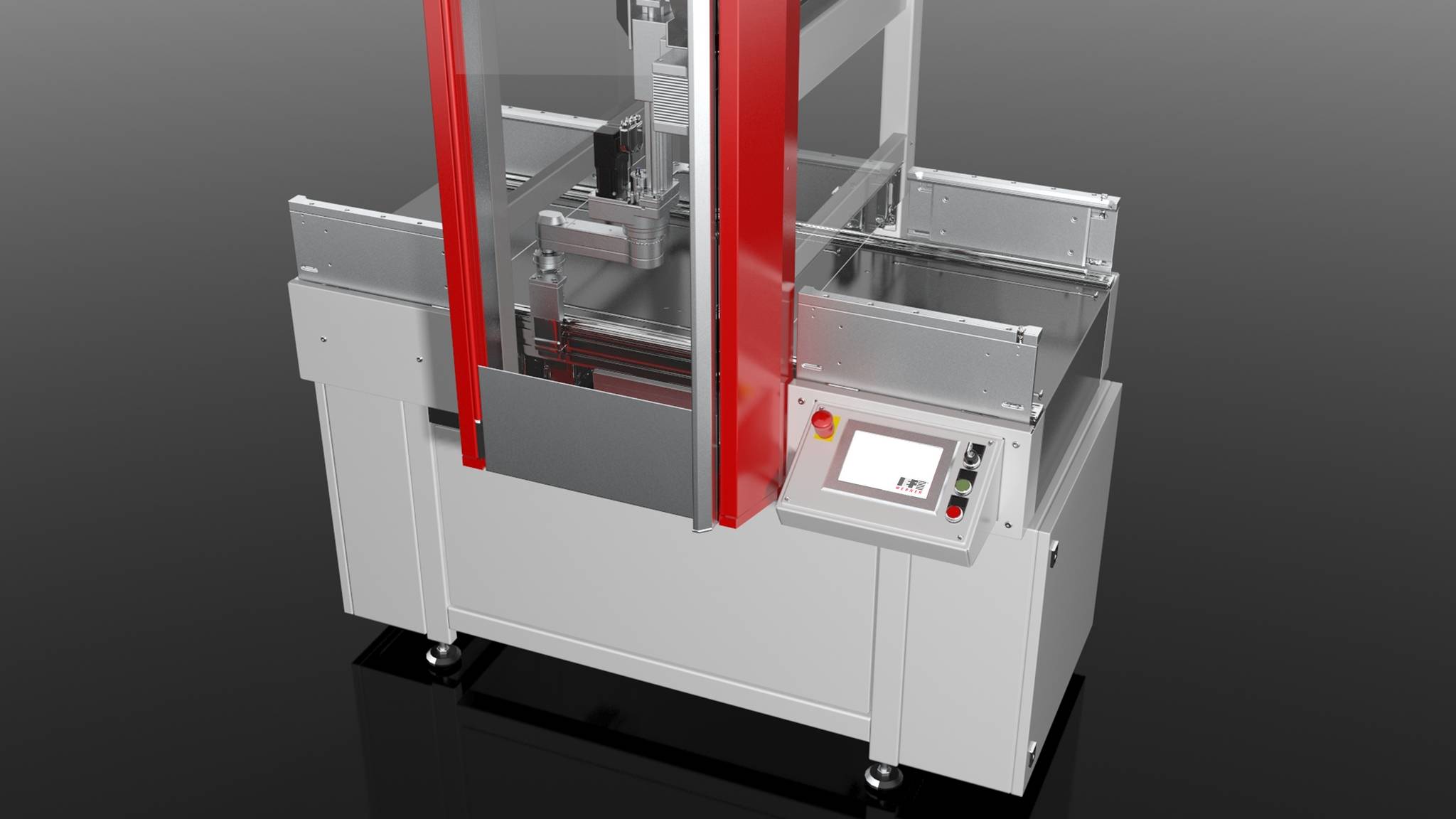

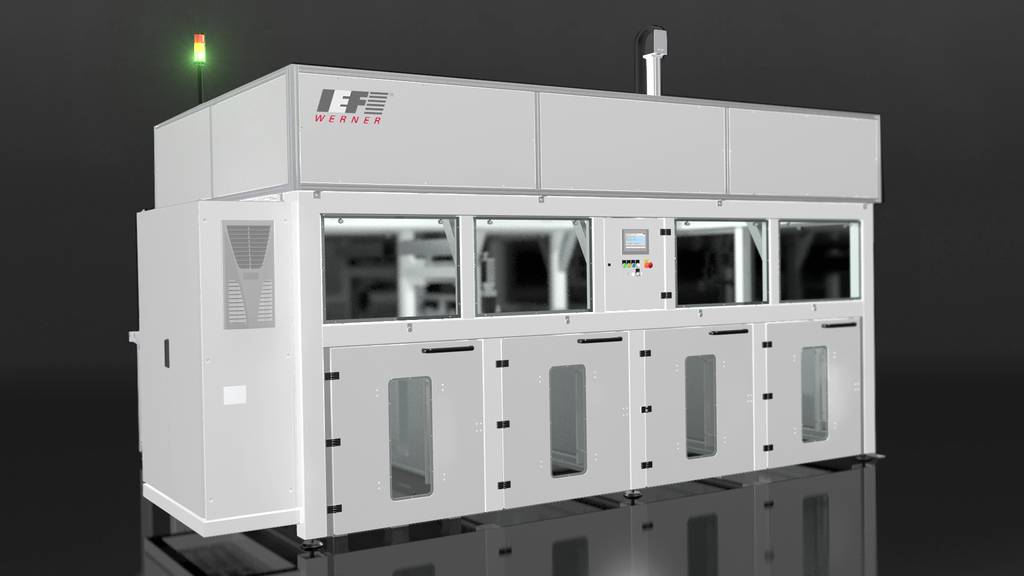

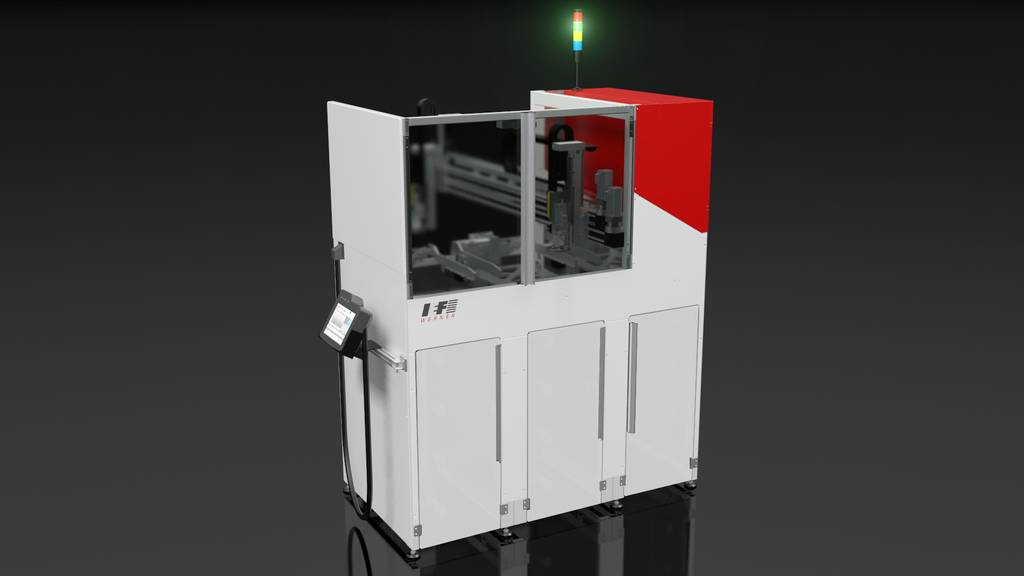

Palletisers

Palletiser for optimised material flow

In state-of-the-art assembly plants, orderly and gentle handover of the workpieces is required. Intermediate buffering is often necessary as well. The IEF palletising systems are aligned with flexible factory automation and demand-oriented material flow. All versions are particularly suitable for integration into processing centres, Scara robots and transport routes. Servo motors with absolute value technology are used for driving, which makes reference runs - e.g. at restart or opening of doors - unnecessary. Of course, in addition to the standard pallets named special sizes can be processed as well.

In 6 steps to your palletising system

The IEF-palletiser system is extremely versatile. A great number of optional components make it possible to adapt the IEF-palletiser system to your desires almost as needed. Therefore, it is important not to lose track.

The online tool supports you in configuring and requesting your palletising system. With just a few clicks, you can adapt the palletising system specifically to your requirements and send an enquiry to our sales team.

-

Handling with added value

-

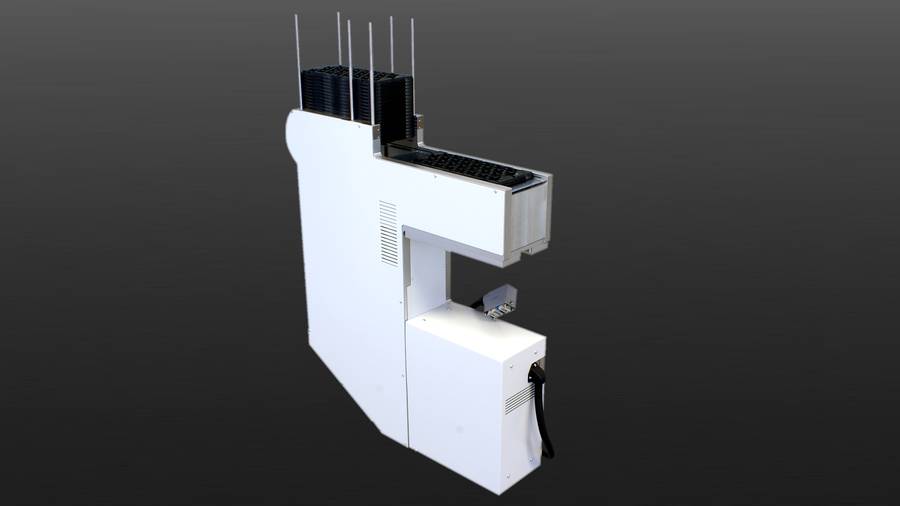

Application example: Automated guided vehicles (AGVs)