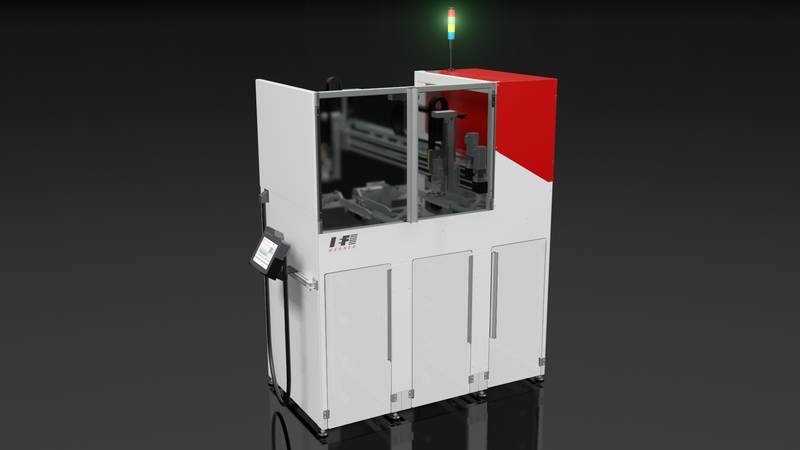

Flexible & fully automatic

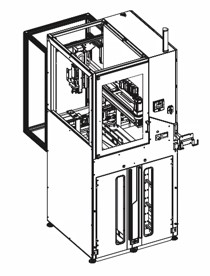

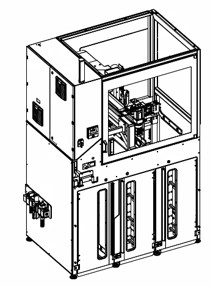

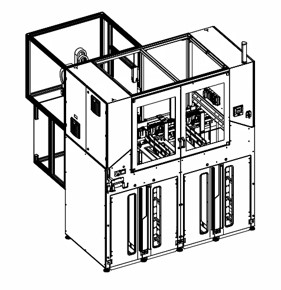

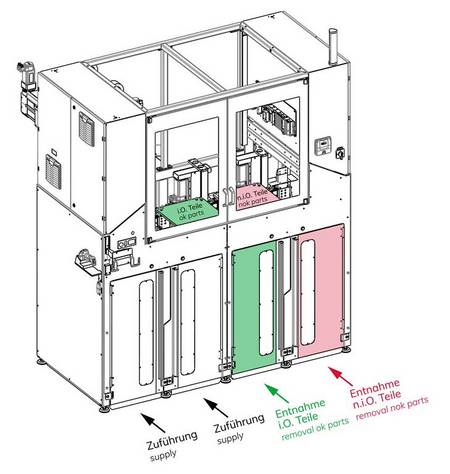

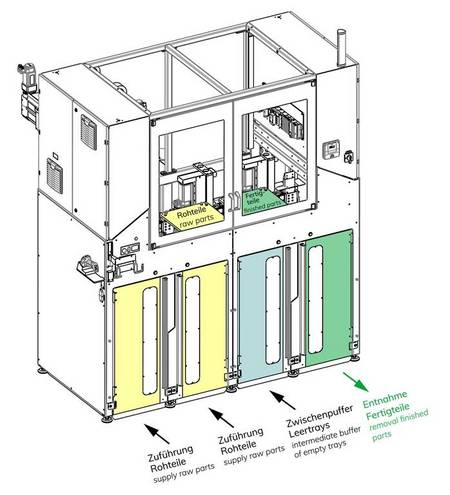

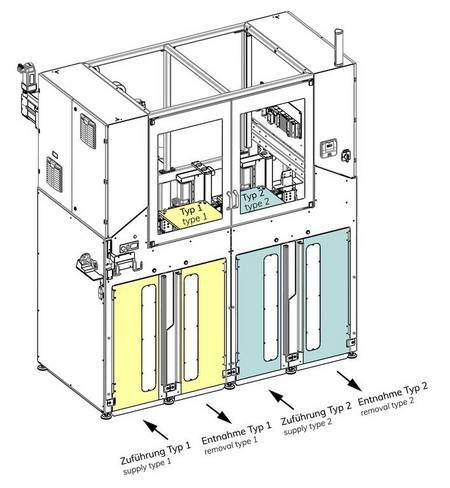

Our palletising systems stand for top quality and performance. Our portfolio includes multi-shaft palletisers that are used in a wide range of industries and can be optimally adapted to customer requirements. They ensure the quality of your products and provide a high degree of autonomy

The palletising of trays or KLTs on standard floor rollers is also possible as well as the connection to AGVs (automated guided vehicles). AGVs offer the possibility of automating material transports such as pallet stacks. We optimise your processes, supply turnkey systems and are there for you from planning to implementation.