A stack of 10 pallets with a strap is manually put onto the table deposit. The foil is removed from the stack, the lid from the top pallet and placed on the posyART transport belt. Every second pallet is stacked turned by 180°. The pallets run into the unstacking station and are pushed in the stack storage by a lift. There, they are inspected for position (0°; 180°) and put down on the belt in sequence via a handle separation. The separated pallets run into the turning station, where they are turned by 180° if necessary. Then they are taken on to the receiving position for the two servo-motor quick-intake systems, sucked on by a form locking mechanism on the pallet receptacle plate and run to the unloading station by the quick intake. Parts handling with a 4-fold forked gripper encloses the component series and puts it down onto a transport belt with workpiece carriers. On it, they are supplied to the further assembly process. Each pallet is unloaded in four passes while the next one is already pre-positioned on the second quick intake system. The emptied pallets are run to the stacker at the end of the machine with the quick intake and stacked at max. 70 empty pallets. They can be manually removed from there.

- Ideas are our core competence

- +49 7723/925-0

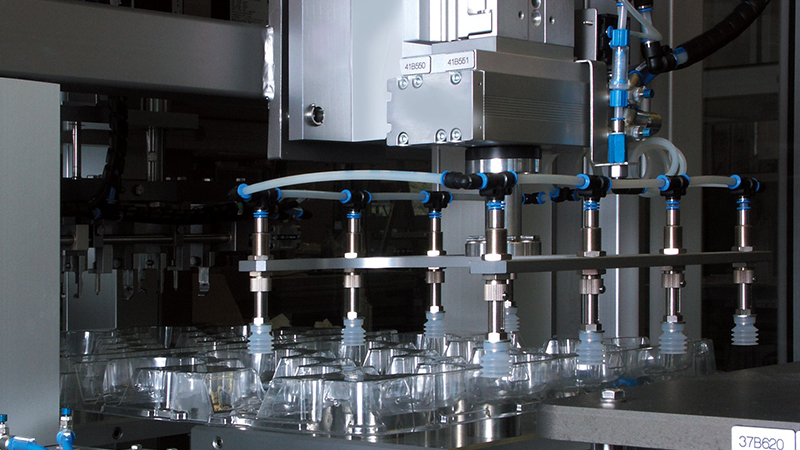

PSO for medical technology

- Product type: Customer applications