- Ideas are our core competence

- +49 7723/925-0

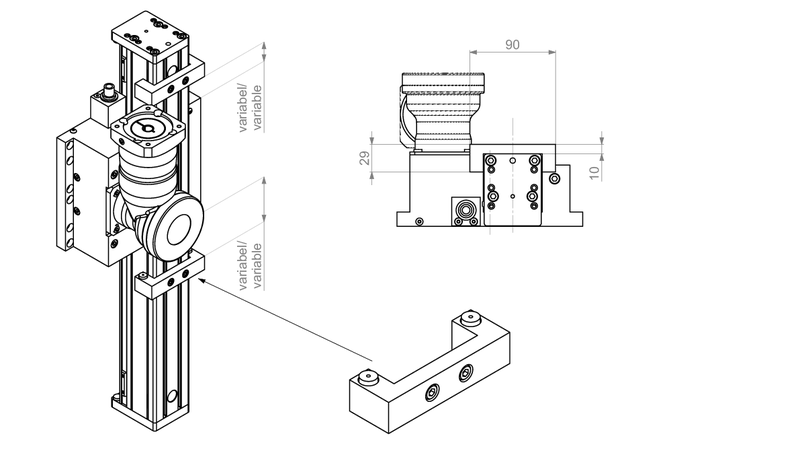

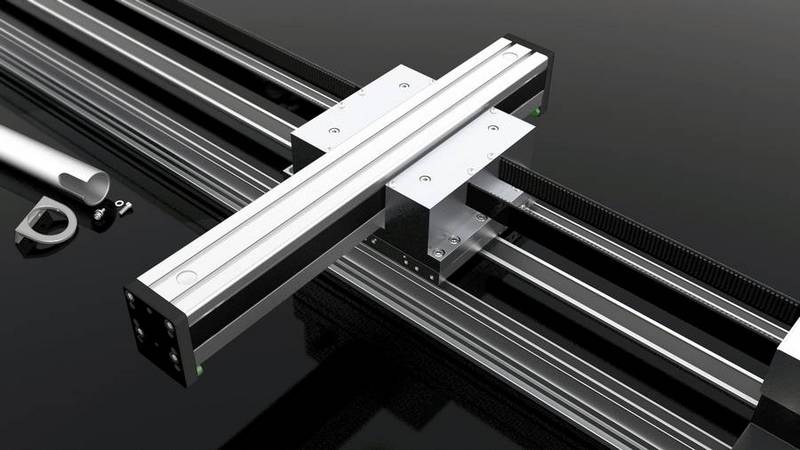

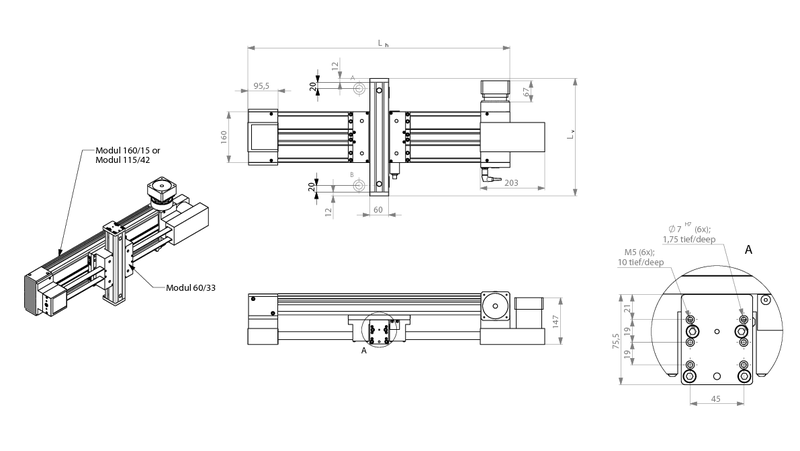

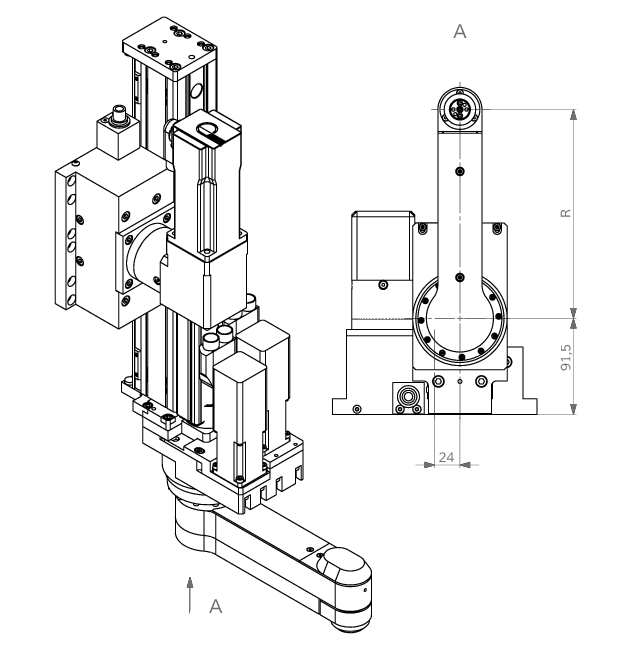

2-axis positioning system AL 2/17

- Product type: Linear drives

- Download

- CAD data: 2-axis positioning system AL 2/17

- CAD data: Levelling elements

-

Technical details AL 2/17

-

Technical details x-axis

Lh (special lengths on request) 524, 624, 724 ... 1924 mm A,B optional stroke limit, end position switch stroke (stroke increments 100 mm) 100 - 1500 mm weight at 100 mm stroke 10.4 kg weight increase per 100 mm stroke 1.4 kg maximum movement speed 5 m/s toothed belt width 50 mm tensile strength toothed belt 4200 N geometrical moment of inertia of the basic body Ix 1.196.016 mm4 / Iy 8.689.482 mm4 -

Technical details z-axis

Lv (special lengths on request) 329 mm, 369 mm, 409 mm…1329 mm stroke (stroke increments 40 mm) 100-1100 mm A, B optional stroke limit, end position switch total weight at 100 mm stroke 8 kg (without motor and gear) thereof moving mass 3.07 kg (at 100 mm stroke) weight increase per 40 mm stroke 0.24 kg maximum movement speed 2.2 m/s (depending on load and gear) repeat accuracy +/- 0.05 mm toothed belt width 25 mm / AT5 tensile strength toothed belt 2 x 1750 N tear out force toothed belt 2 x 4000 N geometrical moment of inertia of the basic body Ix 426.000 mm4 / Iy 451.000 mm4 infeed constant without gear 80 mm/rotation standard reductions planetary gear 3:1 4:1 5:1 7:1 8:1 10:1 recommended max. load in vertical operation 15 kg (depending on stroke, motor and gear) cross assembly to Module 160/15, Module 115/42 -

Features

- when driving the z-axis, neither motor nor cables are moved along

- small mass to be moved

- 15% shorter cycle times

- no cable wear

- time and therefore cost saving construction by doing without a complex energy supply system

- open to attach any desired servo motor

- simple control without complex interpolation

- large strokes and self-supporting construction possible

-

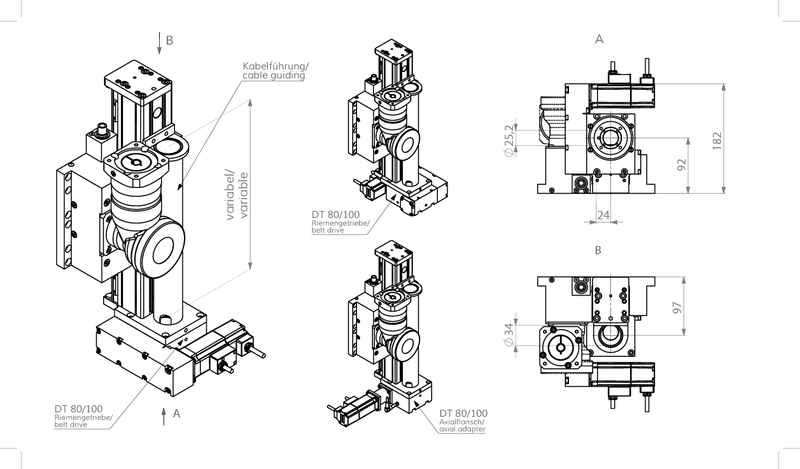

Accessories: NC-rotary unit DT 80/100

The basic construction consists of a rotary table DT 80/100. For the NC-operation per stepper or servo motor, corresponding motor flanges incl. pluggable coupling systems are available. For motors with resolver system, a reference point switch is used.

- output torque up to 20 Nm

- inductive reference point switch

- high axial load

-

Accessories: Swivel arm module rotaryARM

The swivel arm module rotaryARM in connection with Module 60/33 is a very fast pick-&-place system for all tasks that require quick and precise automation solutions. It has a range of 297, 399 or 537 mm.

- NC-swivel arm module with optional gripper turning

- endless turning at swivel axis and gripper turning

- short cycle time by overlaying speed of swivel arm and linear axis

- rotary feedthrough for pneumatics and electrics integrated in swivel arm and gripper turning, thus no external energy guiding necessary

- servo motors with high-resolution absolute value encoders

- large stiffness and low net weight

- NC-swivel arm module with optional gripper turning

- endless turning at swivel axis and gripper turning

- short cycle time by overlaying speed of swivel arm and linear axis

- rotary feedthrough for pneumatics and electrics integrated in swivel arm and gripper turning, thus no external energy guiding necessary

- servo motors with high-resolution absolute value encoders

- large stiffness and low net weight

-

Accessories: Planetary gear with motor

-

Accessories: Mechanic stopper

-

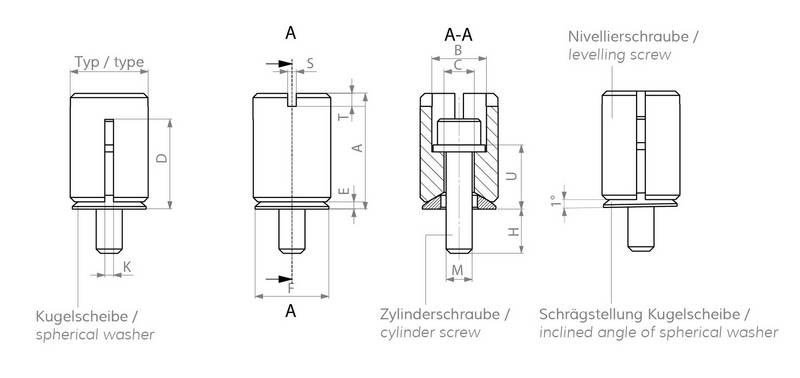

Accessories: Levelling elements

These elements are ideal for the levelling of assembly surfaces which cannot be mechanically processed or only with great effort. You can find more information and helpful tutorials here.

-

Video: Functionality of the drive of two axes