- Ideas are our core competence

- +49 7723/925-0

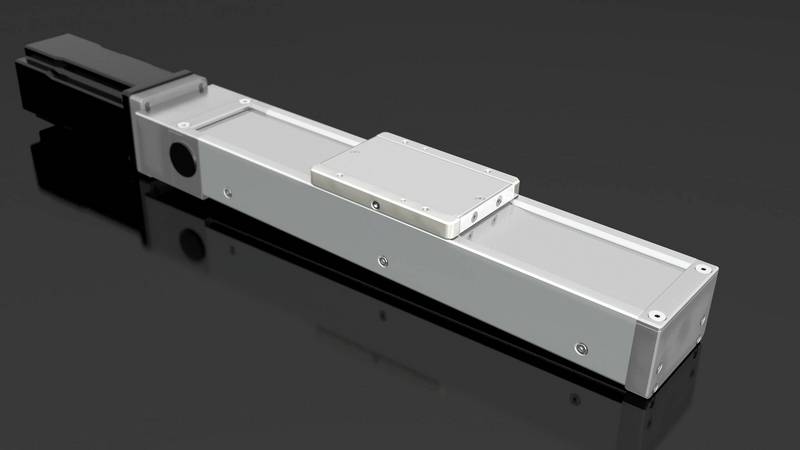

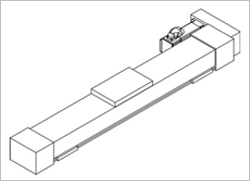

profiLINE 70 MB

- Product type: Linear drives

- CAD data: profiLINE 70 MB

- CAD data: Levelling elements

-

General details

-

Test results of the clean room examination by Fraunhofer IPA

-

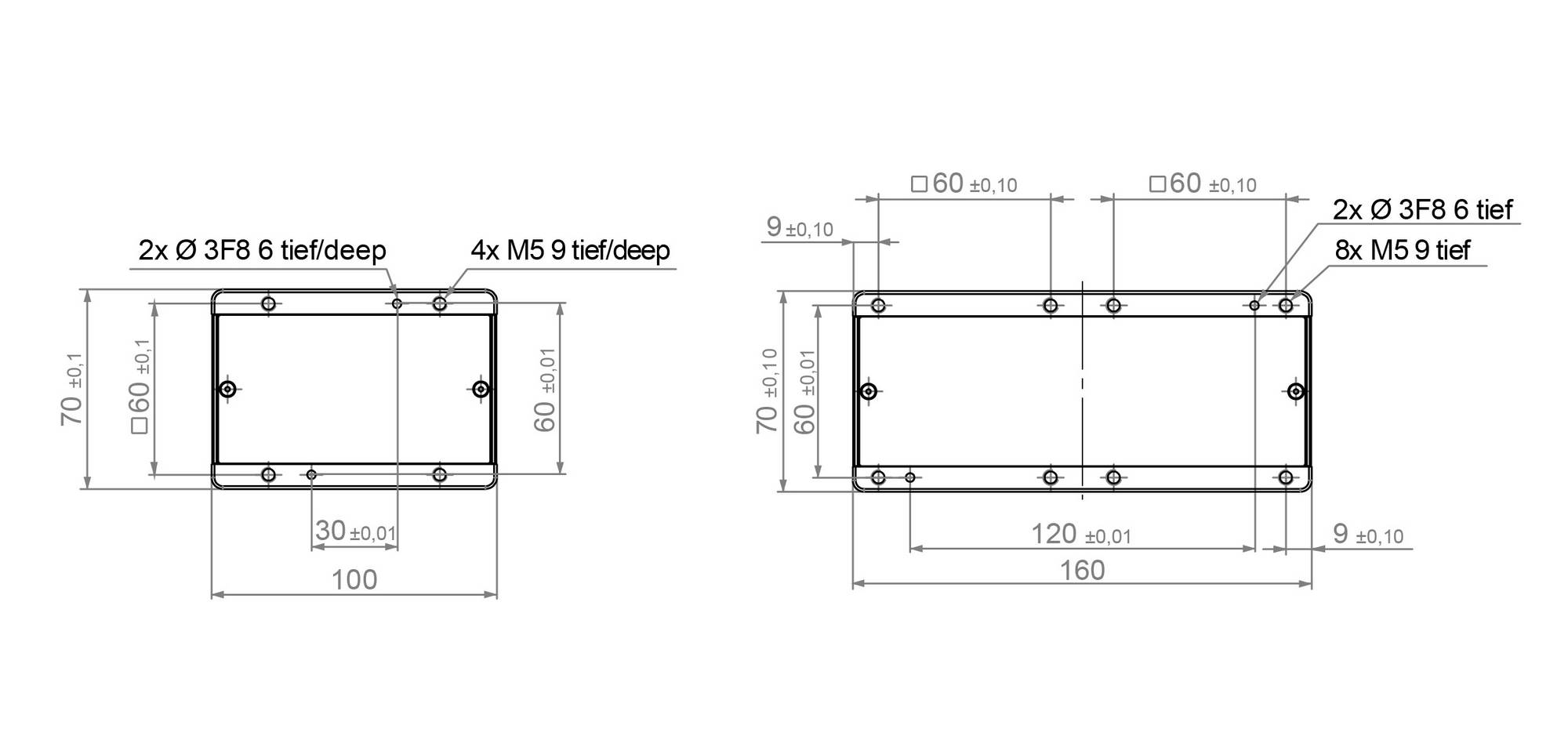

Slide variants

-

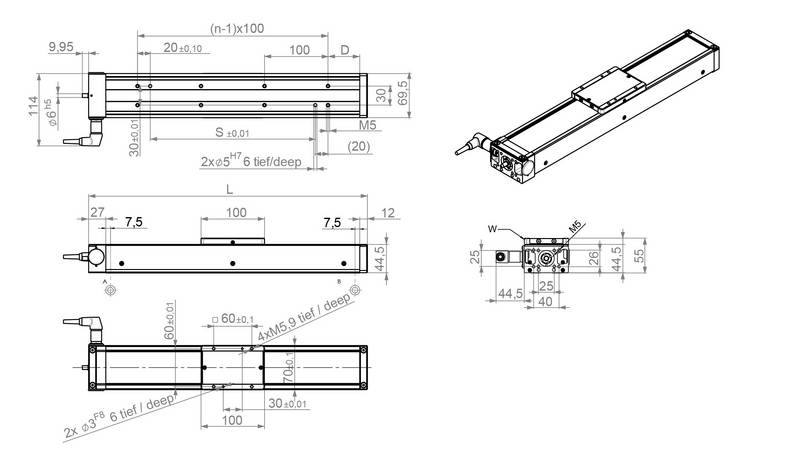

Technical details

weight basic slide unit (35 mm stroke) 2,65 kg weight increase (per 100 mm stroke) 0,63 kg weight slide (70 mm long) 1 kg possible spindle pitch 5 mm / 10 mm repeat accuracy +/- 0.003 mm process accuracy (at 300 mm stroke) 0,015 mm max. spindle rotation speed 4000 1/min positioning accuracy <= 0,025 mm geometrical moment of inertia of the basic bodydes Grundkörpers Ix 20.536 mm4 / Iy 280.543 mm4 basic friction torque 0,1 Nm -

Version with standard cover

The spindle drive is also available in a version with standard cover. The profiLINE 70 is proven in many different industries and have been successfully used for years as ready-to-install module. It is mostly used in handling technology and factory automation.

-

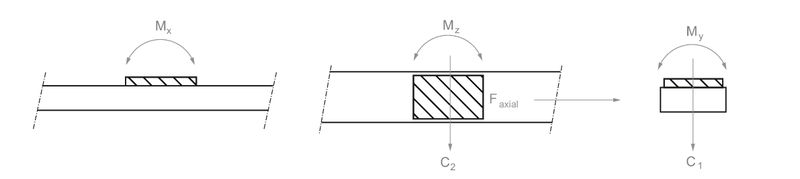

Loading details

-

Motor assembly variants

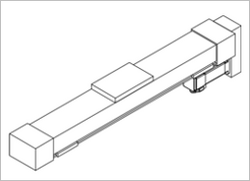

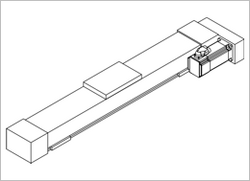

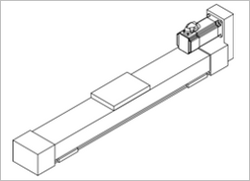

Variant 0

Variant 1

Variant 2

Variant 3

Variant 4

Variant 5 The motors are attached either directly or via a near-play-free belt gear. Different attachment versions and transmission ratios are available. Attachment type and transmission ratio can be changed easily subsequently as well. A planetary gearbox is available for all attachment variants.

-

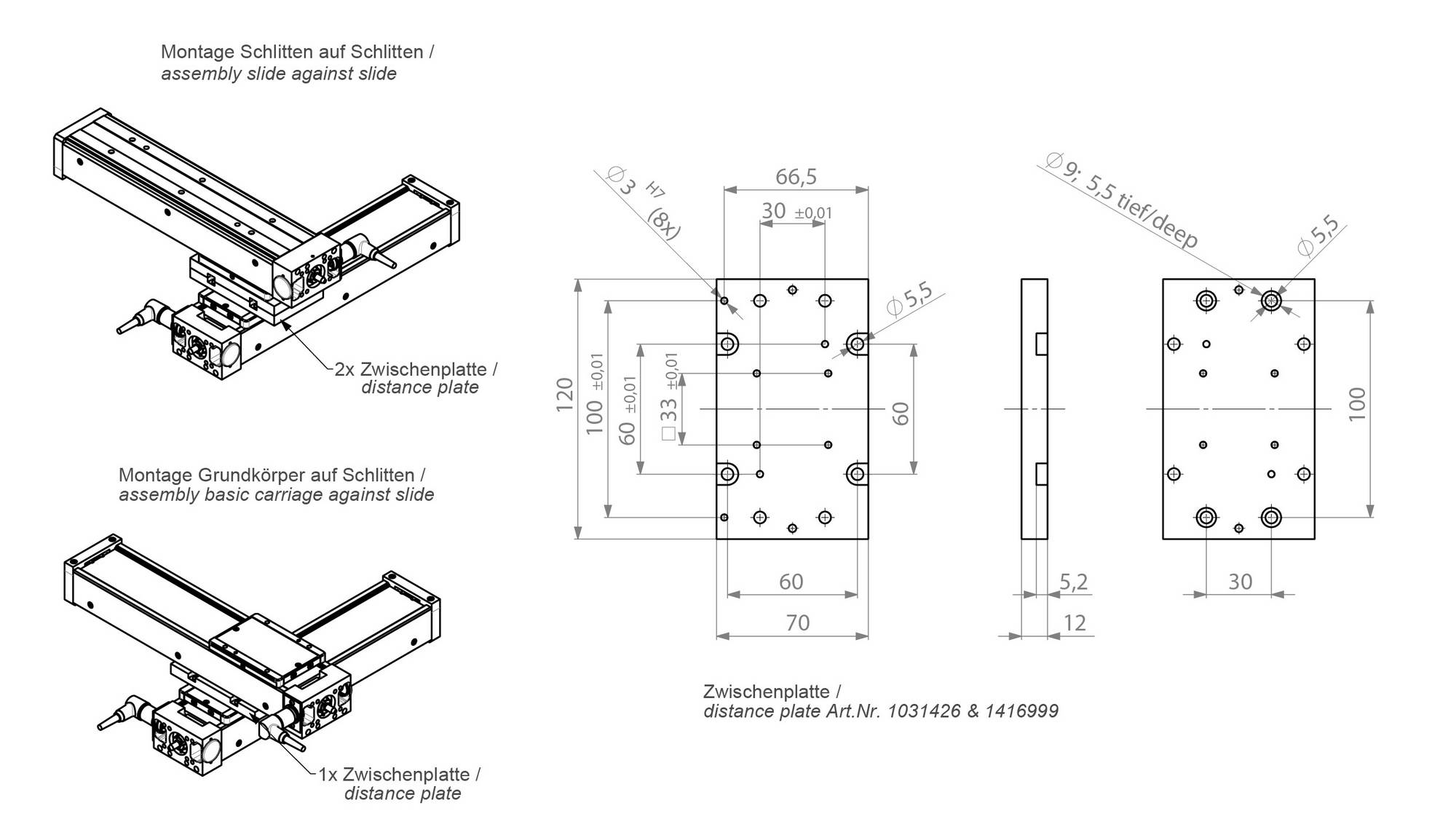

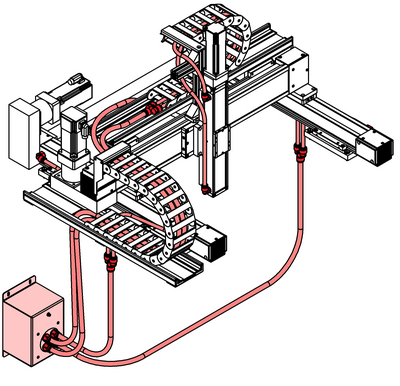

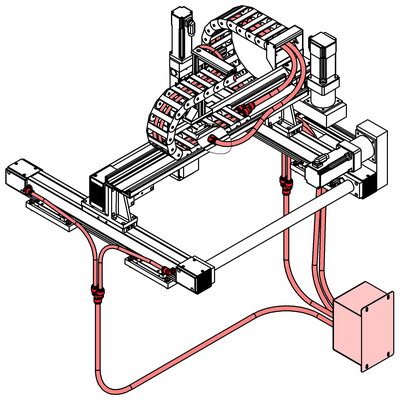

Accessories: xy-assambly

-

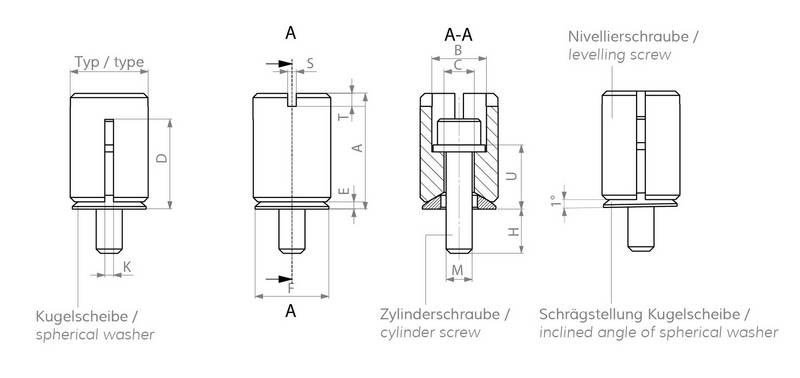

Accessories: Levelling elements

These elements are ideal for the levelling of assembly surfaces which cannot be mechanically processed or only with great effort,. You can find more information and helpful tutorials here.

-

Accessories: Extraction or sealing air system