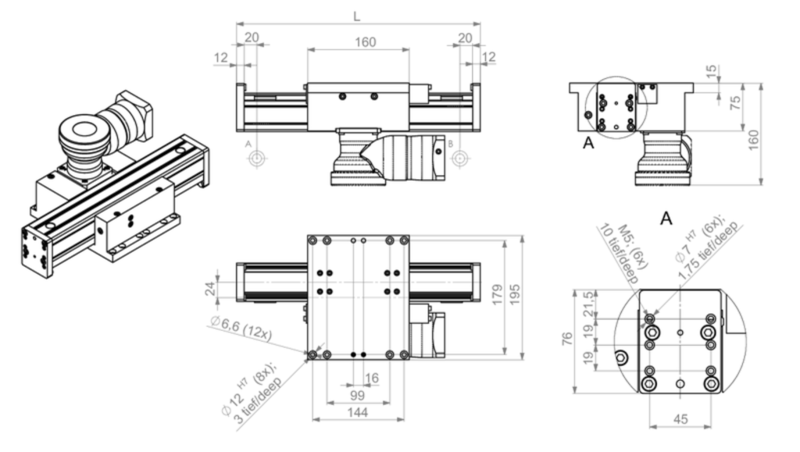

| length L | 329 mm, 369 mm, 409 mm…1329 mm |

| stroke | 100-1100 mm (stroke increments 40 mm) |

| A, B | optional stroke limit, end position switch |

| total weight at 100 mm stroke | 7 kg (without motor and gear) |

| thereof moving mass | 3,07 kg (at 100 mm stroke) |

| weight increase per 40 mm stroke | 0,24 kg |

| max. movement speed | 2,2 m/s (depending on load and gear) |

| repeat accuracy | +/- 0,05 mm |

| toothed belt width | 25 mm / AT5 |

| tensile strength toothed belt | 2 x 1750 N |

| max. input torque | 3.6 Nm |

| frictional torque | 0.3 Nm |

| tear out force toothed belt | 2 x 4000 N |

| geometrical moment of inertia of the basic body | Ix 426.000 mm4, Iy 451.000 mm4 |

| infeed constant without gear | 75 mm/rotation |

| standard reductions planetary gearbox | 3:1, 4:1, 5:1, 7:1, 8:1, 10:1 |

| recommended max. load | 15 kg (depending on stroke, motor and gear) |

| cross assembly to | Module 160/15, Module 115/42 |

- Ideas are our core competence

- +49 7723/925-0

Module 60/33

- Product type: Linear drives

- Download

- CAD data: Module 60/33

- CAD data: Levelling elements

- Operating instructions

-

Technical details

-

Product details

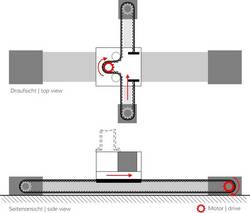

The toothed belt driven linear unit Module 60/33 convinces with a new drive concept. Hereby, the toothed belt is specifically guided and uses the principle of the hoist. The special profile construction as well as the continuous profile rail guide ensure maximum bending stiffness. These measures allow higher speeds as well as heavier loads. The toothed belt axis can be used - horizontally or vertically - as stand-alone or multiple-axis system. Also the adaption possibilities of the accessories were optimised, as for example of turning and swivel drives.

- stroke up to 1100 mm

- speed in vertical operation up to 2.2 m/s

- max. load in vertical operation: 15 kg

-

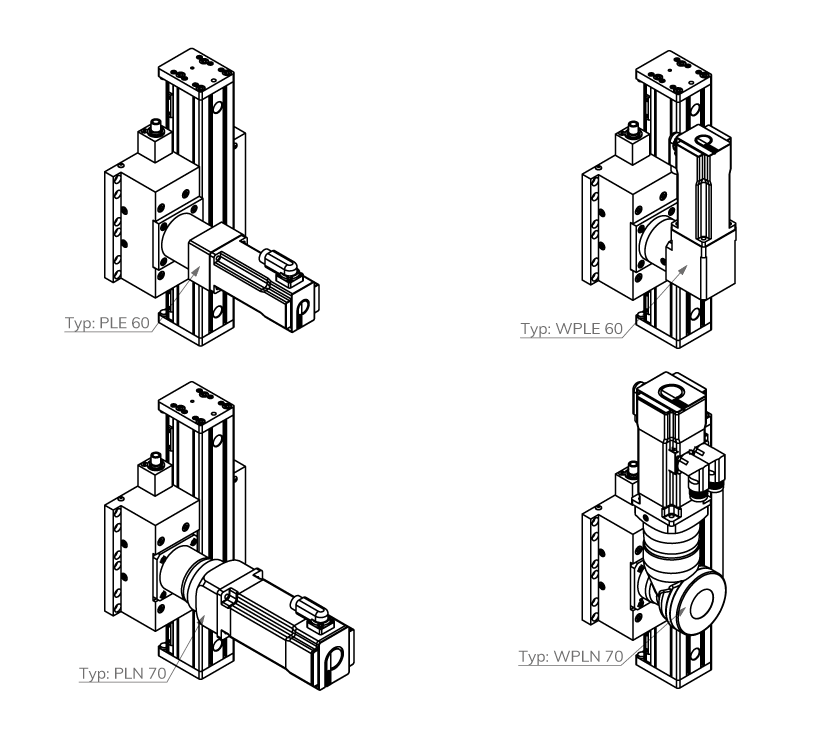

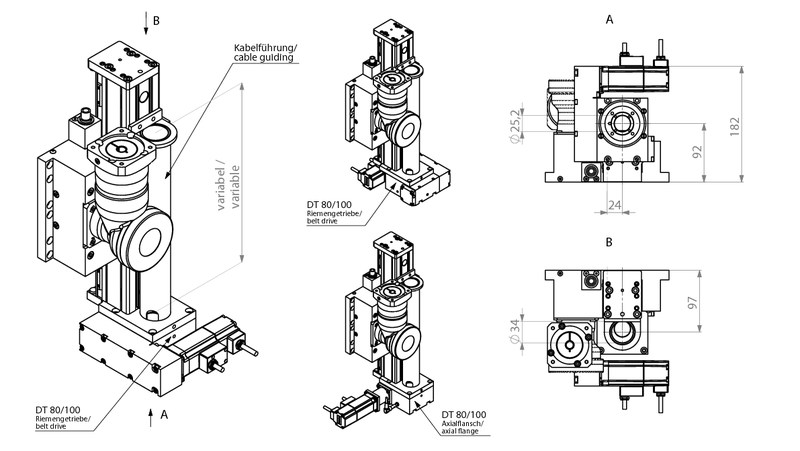

Motor assembly variants

-

Accessories: NC-rotary unit DT 80/100

The basic construction consists of a rotary table DT 80/100. For the NC-operation per stepper or servo motor, corresponding motor flanges incl. pluggable coupling systems are available. For motors with resolver system, a reference point switch is used.

- output torque up to 20 Nm

- inductive reference point switch

- high axial load

-

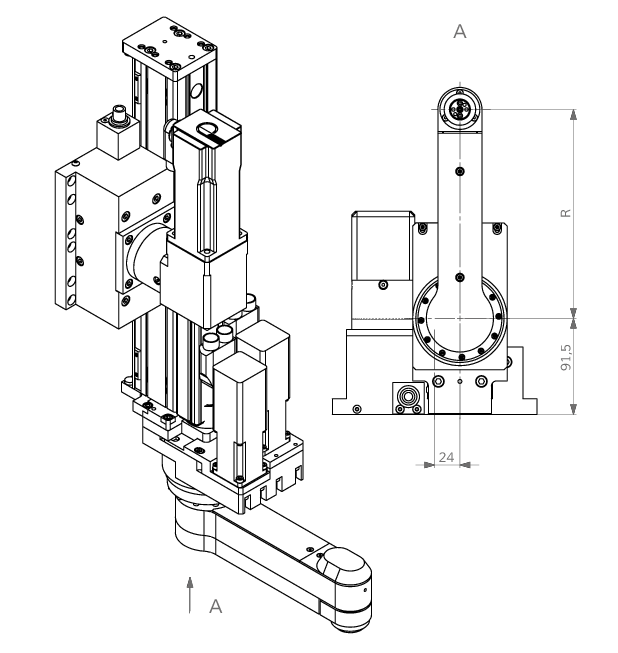

Accessories: Swivel arm module rotaryARM

The swivel arm module rotaryARM in connection with Module 60/33 is a very fast pick-&-place system for all tasks that require quick and precise automation solutions. It has a range of 297, 399 or 537 mm.

- NC-swivel arm module with optional gripper turning

- endless turning at swivel axis and gripper turning

- short cycle time by overlaying speed of swivel arm and linear axis

- rotary feedthrough for pneumatics and electrics integrated in swivel arm and gripper turning, thus no external energy guiding necessary

- servo motors with high-resolution absolute value encoders

- large stiffness and low net weight

-

Accessories: Planetary gear with motor

-

Accessories: Mechanical stop

-

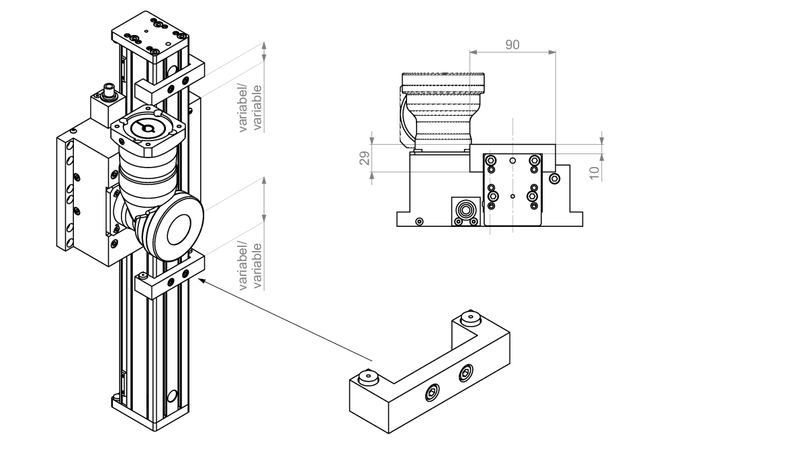

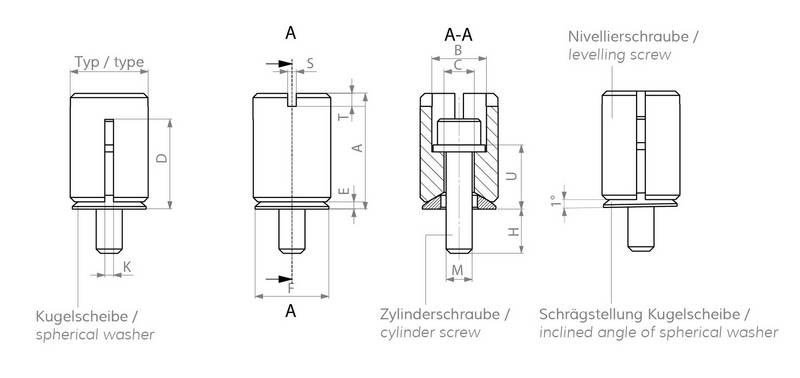

Accessories: Levelling elements

These elements are ideal for the levelling of assembly surfaces which cannot be mechanically processed or only with great effort, You can find more information and helpful tutorials here.