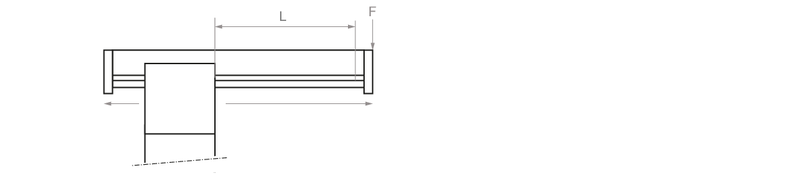

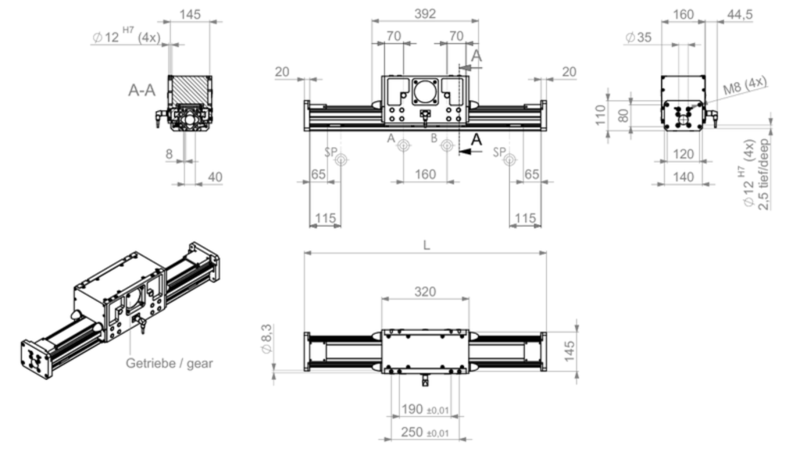

| L | 490, 550, 610 ... 1930 mm |

| A,B | stroke limit, end position switch |

| stroke (stroke increments 60 mm) | 60 - 1500 mm |

| weight at 60 mm stroke | 25.3 kg |

| weight increase per 60 mm stroke | 0.74 kg |

| maximum movement speed | 1.2 m/s |

| repeat accuracy | +/- 0.05 mm |

| toothed belt width | 50 mm |

| tensile strength | 8500 N |

| max. input torque | 48.1 Nm |

| frictional torque | |

| geometrical moment of inertia of the basic body | Ix 1.877.000 mm4 / Iy 1.877.000 mm4 |

| infeed constant without gear | 220 mm |

| max. load in vertical operation | 40 kg |

- Ideas are our core competence

- +49 7723/925-0

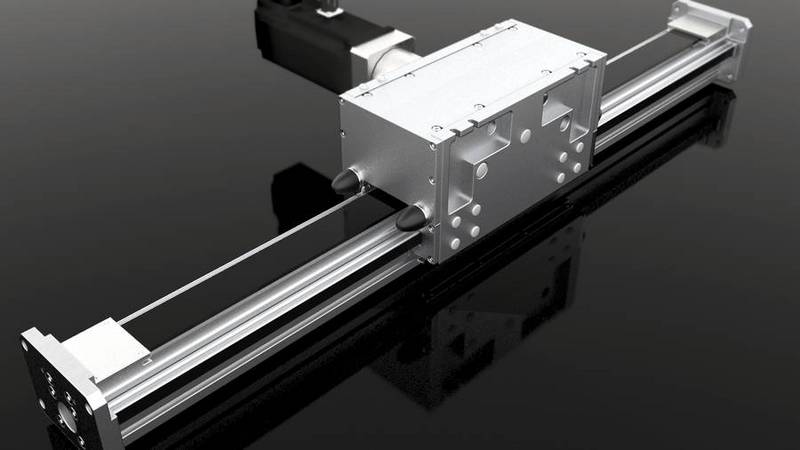

Module 160/20 ZR10

- Product type: Linear drives

- Download

- CAD data: Module 160/20 ZR10

- CAD data: Levelling elements

- Operating instructions

-

Technical details

-

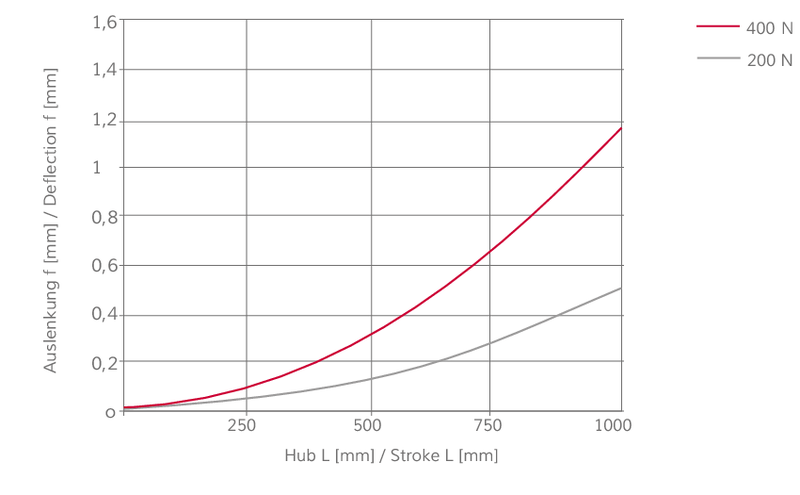

Max. load in cantilever operation

-

Bending stiffness

-

Locking brake for vertikal axis

Note: The locking brake serves as a redundant brake and may only be used in addition to a motor brake or other primary brake.

The linear unit with braking element LBPS is designed exclusively for operation with compressed air. It is not suitable for operation with other media. According to EN ISO 13849-1, the integrated braking element is a proven component of control systems. The element can be used in category B or 1 control systems without any further control measures; a test channel must be provided for category 2 control systems. For use in higher control categories, the control must be multi-channel, whereby each channel must implement the safety function on its own.

-

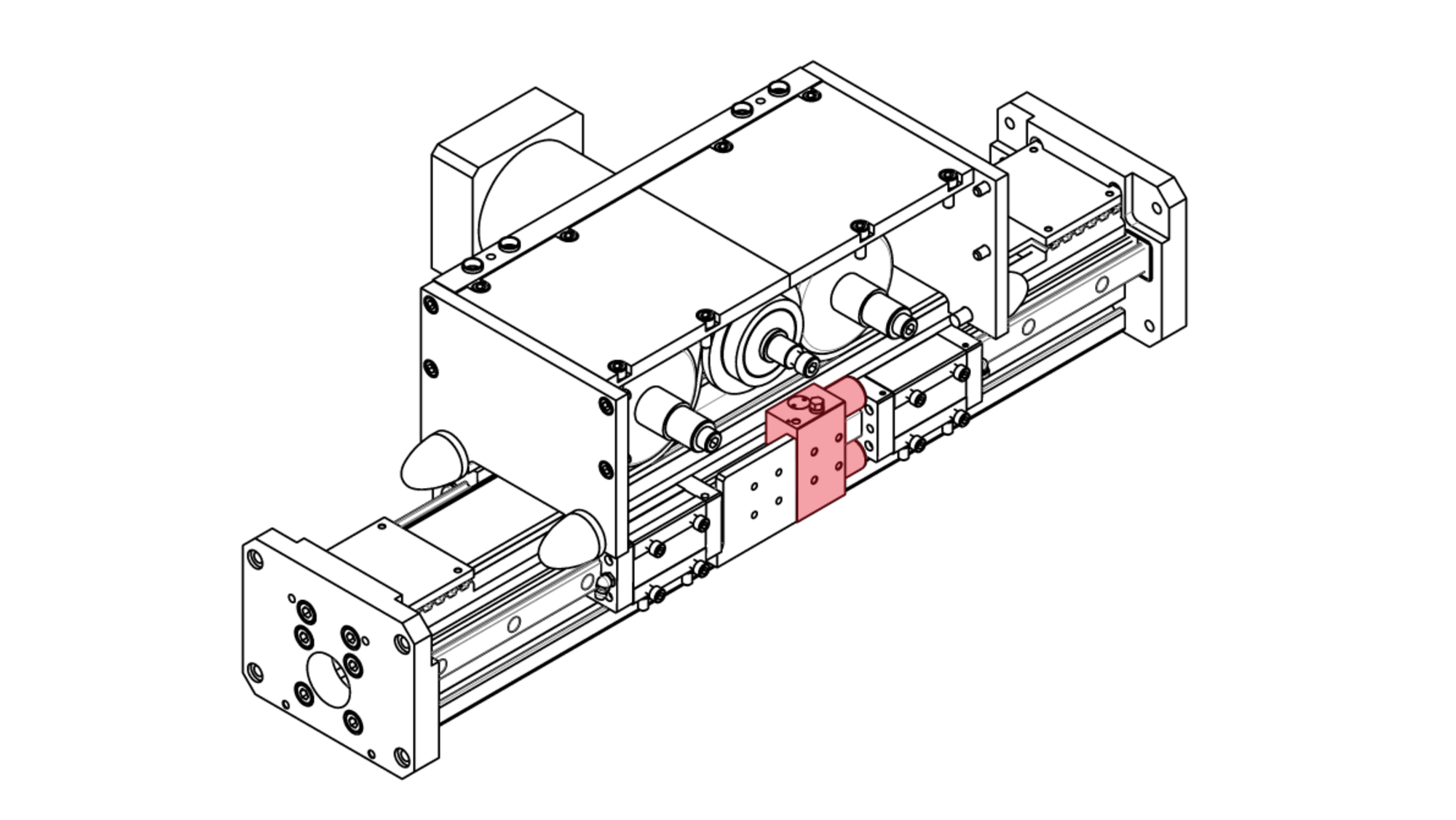

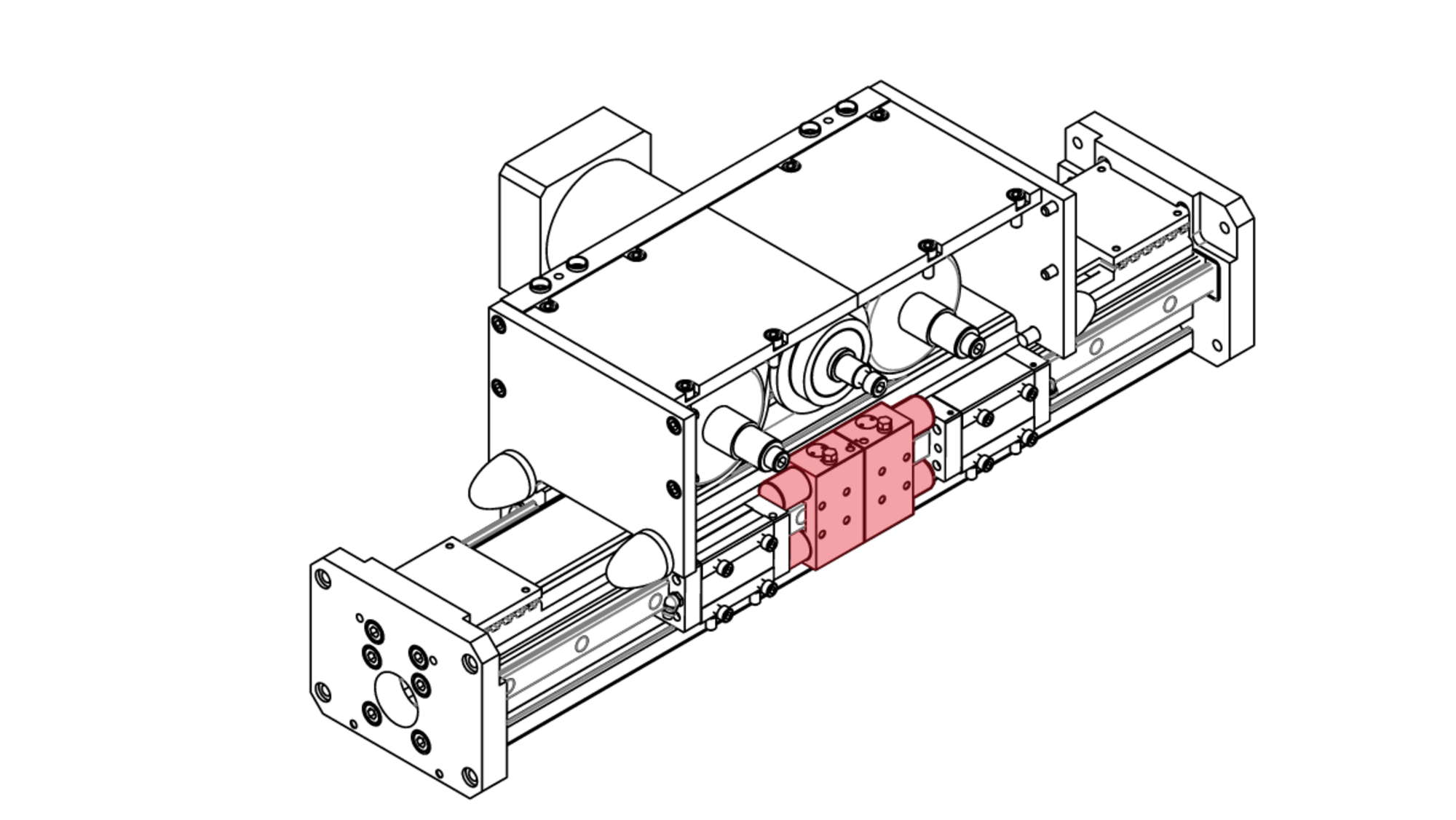

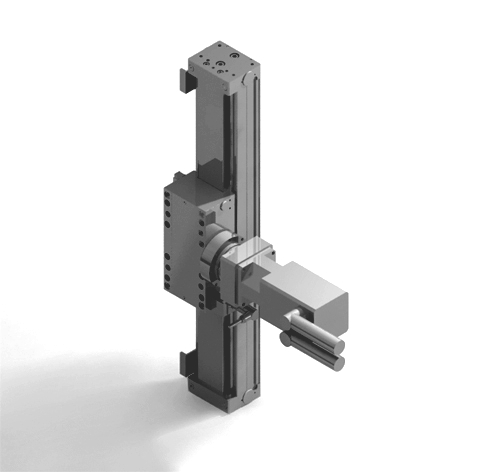

Motor assembly variants

-

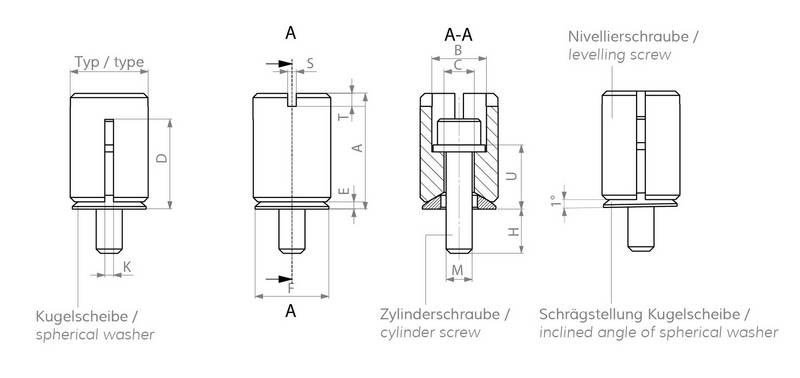

Accessories: Levelling elements

These elements are ideal for the levelling of assembly surfaces which cannot be mechanically processed or only with great effort. You can find more information and helpful tutorials here.